Home > Product > Gas turbine system > GE DS2020PDMAG4 Redundant channel module

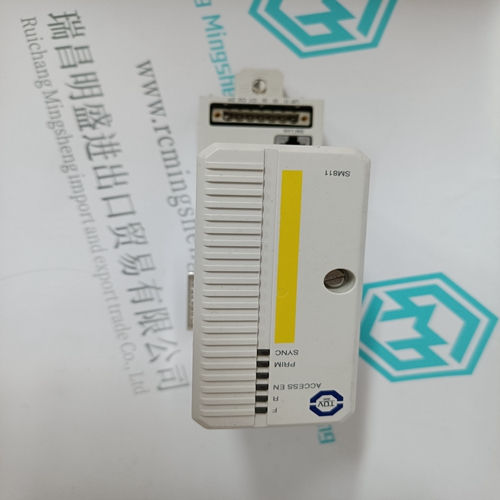

GE DS2020PDMAG4 Redundant channel module

- Product ID: DS2020PDMAG4

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GEDS2020PDMAG4Redundant channel module

- Get the latest price:Click to consult

GE DS2020PDMAG4 Redundant channel module

Manual cleaning Procedure 1. Do not use toxic or flammable solvents to clean control system hardware. 2. Turn off electrical power (lock out) before cleaning control system assemblies. 3. Keep electrical panel covers closed and power off when cleaning an enclosure. 4. Always clean up spills around the equipment immediately after they occur. 5. Never attempt to clean a control system while it is operating. Never use water to clean control equipment unless you are certain that the equipment has been certified as sealed against water ingress. Water is a very good conductor of electricity and the single largest cause of death by electrocution.

The MMC offers a complete solution to both machine

motion control in a stand-alone unit. The MMC family includes these models: • MMC-A2 (2 1/2 axis analog servo control) • MMC-A4 (4 1/2 axis analog servo control) • MMC-S8 (8 axis SERCOS control) (future) The PiCPro for Windows programming tool used with the PiC family of controls is also used to program the MMC. The built-in I/O [up to 28 inputs (24 VDC) and 16 outputs (24 VDC)] can be expanded using Giddings & Lewis serially distributed block I/O. There are also eight (four) low current DC outputs and four (two) DC inputs on the Axis connectors of the MMC-A4 (MMC-A2).

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/