Home > Product > PLC programmable module > BENTLY 3500/05-02-04-00-00-00 Monitor framework

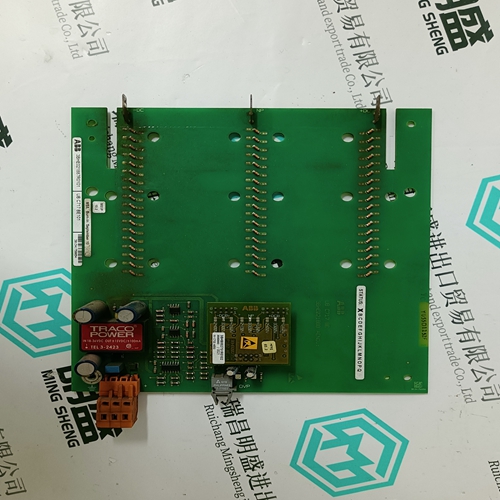

BENTLY 3500/05-02-04-00-00-00 Monitor framework

- Product ID: 3500/05-02-04-00-00-00

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY 3500/05-02-04-00-00-00Monitor framework

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

BENTLY 3500/05-02-04-00-00-00 Monitor framework

Low Battery Low Battery signal is a Normally Open (NO) dry contact. When the UPS is supplying output power from the battery and has reached the Low Battery Warning time selected in the configuration program, this dry contact will be closed. The rated values for the dry contacts for the On Battery and Low Battery signals are: • Rated Voltage: 30 V (AC or DC) • Rated Current: 300 mA

This section describes replacing the internal battery pack, precautions, checking the UPS status and checking UPS functions. WARNING! Risk of electric shock. Can cause equipment damage, injury and death. A battery can present a risk of electrical shock and high short-circuit current. The following precautions should be observed when working on batteries: • Remove watches, rings and other metal objects. • Use tools with insulated handles. • Wear rubber gloves and boots. • Do not lay tools or metal parts on top of batteries. • Disconnect charging source prior to connecting or disconnecting battery terminals. • If the battery kit is damaged in any way or shows signs of leakage, contact your Vertiv™ representative immediately. • Handle, transport and recycle batteries in accordance with local regulations. • Determine if the battery is inadvertently grounded. If it is inadvertently grounded, remove the source of the ground. Contact with any part of a grounded battery can result in electrical shock. The likelihood of such shock will be reduced if grounds are removed during installation and maintenance (applicable to a UPS and a remote battery supply not having a grounded supply circuit).

Battery Replacement Procedures

Read all safety cautions before proceeding. A trained user can replace the internal battery pack when the UPS is always in a restricted access location (such as a rack or server closet). Contact your local dealer or Vertiv™ representative to obtain the pricing of the appropriate replacement battery pack. CAUTION: Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the instructions. 1. Remove the front plastic bezel cover from the UPS. 2. Loosen and remove the screws on the battery door, as shown in Figure 7.1 below. 3. Lay the battery door and screws aside for reassembly.4. Gently pull the battery wire out and disconnect the battery plug and battery receptacle, as shown in the following figure.5. Grasp the battery handle, and pull the internal battery pack out of the UPS, as shown in the following figure.6. Unpack the new internal battery pack. Take care not to destroy the packing. Compare the new and old internal battery pack to make sure they are the same type and model. If so, proceed with 7. If they are different, stop and contact your Vertiv™ representative, or Technical Support. 7. Line up and slide in the new internal battery pack. 8. Reconnect the battery plug and battery receptacle. 9. Push the battery wire and internal battery pack back into the UPS.10. Reattach the front battery door with the 6 screws. 11. Reattach the front plastic bezel cover to the UPS. NOTE: The internal battery pack is hot-swappable. However, caution should be exercised because during this procedure the load is unprotected from disturbances and power outages. Do not replace the battery while the UPS is operating in Battery Mode. This willresult in a loss of output power and will drop the connected load.