Home > Product > Gas turbine system > UR8AH Relay module

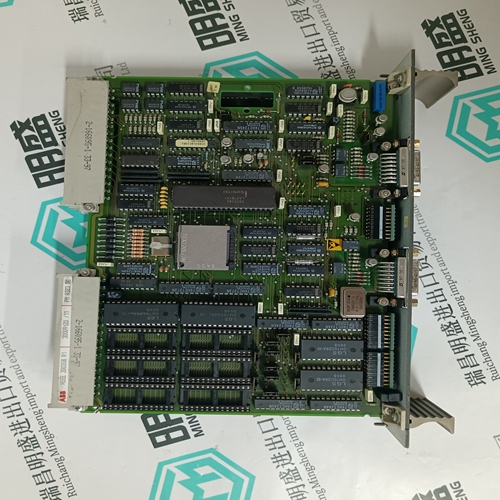

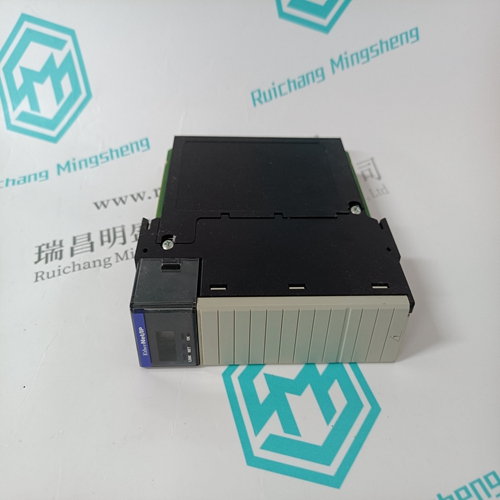

UR8AH Relay module

- Product ID: UR8AH

- Brand: GE

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:UR8AHRelay module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

UR8AH Relay module

The device meets the safety class III in accordance with EN61131-2 and EN50178. The 24V power supply for the equipment must be guaranteed through safe isolation of the low-voltage circuits from dangerous-contact voltage circuits (e.g. by safety transformers or similar facilities).

2.2 Emergency Stop Switch (EN 418 - Safety of Machinery) The emergency stop switch of the handheld terminal meets the requirements of the EN 418 standard, category 0 or category 1. The safety category (in accordance with EN 954) must be defined by means of the risk assessment of the machine according to EN 1050. ❑ As long as the emergency stop switch is not correctly wired in the emergency stop circuit, store the handheld terminal on a place which is out of reach of the operator. Take into account that the operator would automatically activate the nearest emergency stop in case of danger. This could have fatal consequences if the emergency stop did not function! ❑ Emergency stop facilities must remain operational in all operating modes. Resetting an activated emergency stop facility must not result in uncontrolled start-up of machines or installations. ❑ The emergency stop switch does not replace all other safety facilities!

Enabling Switches

At many machines the operator must enter the dangerous area from time to time in order to carry out programming, testing, setting and servicing jobs. This happens in the manual mode of the station, in which the guard is deactivated. This mode must be activated by means of a lockable selector. The enabling switches are used to enable commands for dangerous movements. To meet the safety category 3 in accordance with EN 954-1:1996, the enabling switch must be realised with 2 channels. The draft of the C-standard of the machine tools and machining centres specifies as follows: „An enabling device may be a 2-position device in conjunction with an emergency stop device or a 3-position device. The 3-position device is preferred.“ The EN 60204 describes the functioning of the enabling device. Due to the latest findings of analyses of accidents and since technical solutions are available, the 3-position enabling switch became the state of the art. The positions 1 and 3 of the enabling switch are OFF functions. Only the central position is used for enabling. The EN 60204-1:1997 is identical with the IEC 60204-1. So the 3-position enabling switch is of international importance.