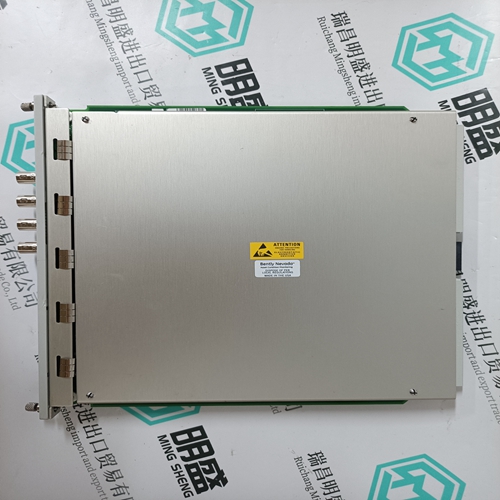

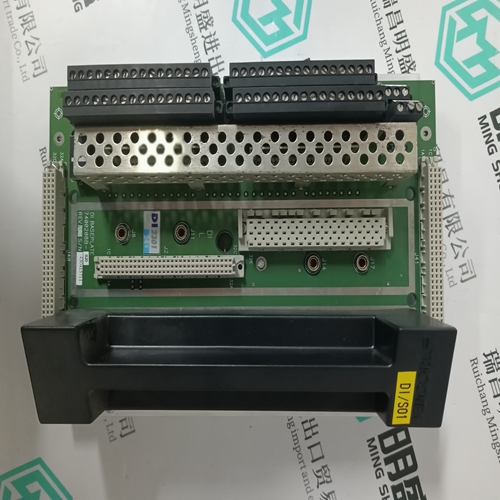

Home > Product > DCS control system > ABB RB510 3BSE003527R1 Dummy Module

ABB RB510 3BSE003527R1 Dummy Module

- Product ID: RB510 3BSE003527R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBRB5103BSE003527R1Dummy Module

- Get the latest price:Click to consult

ABB RB510 3BSE003527R1 Dummy Module

• Permanent Cabling: Cut off cable in excess of approximately 4 inches (10 cm). Configure the motor for series or parallel operation and attach a suitable braided screen cable to the motor, see Motor Cables below. Termination of the braid shield at the motor must be made using a 360° bond to the motor body, and this may be achieved by using a suitable clamp.

Many stepper motors are designed to accommodate

an appropriate terminal gland which can be used for this purpose. If this is not the case, P-clip the braid to the rear end bell of the motor housing, as shown in Figure 4. This will not only provide a good high-frequency bond, but strain relief as well.At the drive end, run the motor cable down to the mounting panel, expose a short length of braiding and anchor to the panel with a P-clip. The ZETA Series require a safety earth connection to the motor (see green and yellow striped wire in Figure 4) — take this from the stud or bus bar. Run the safety earth lead alongside the motor lead. Note that the motor cable should be kept away from I/O cables carrying control signals.

![]()

![]()

Common problem

We have this product in stock, and we can deliver it to you at any time when you need it badly.

*The warranty period of all products is 1 year, which has passed the professional test certification.

*If you need to order more than one product, please contact us, and we can offer you a discount.

*We only use HDL UPS and other express delivery methods to deliver spare parts.

*If you find that other suppliers offer lower prices for the same products, we are also willing to offer you further discounts based on their prices.

If you have any other questions, please feel free to contact us via email.

*Please let us know if you need any spare parts, we can give you further assistance, and we are waiting for your inquiry.

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/