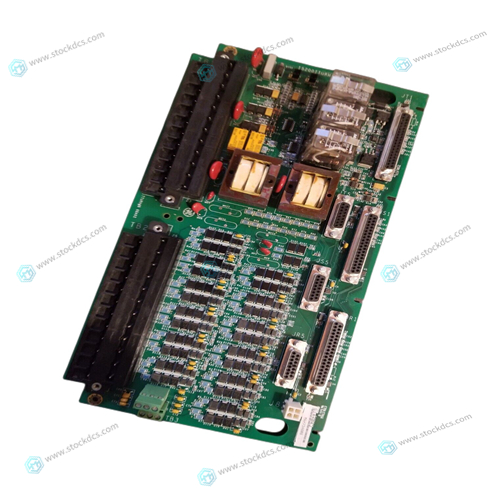

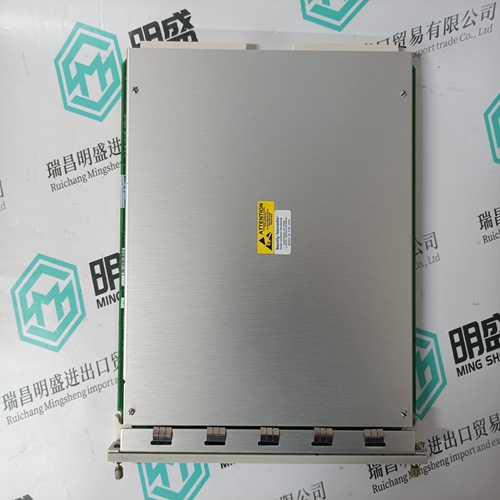

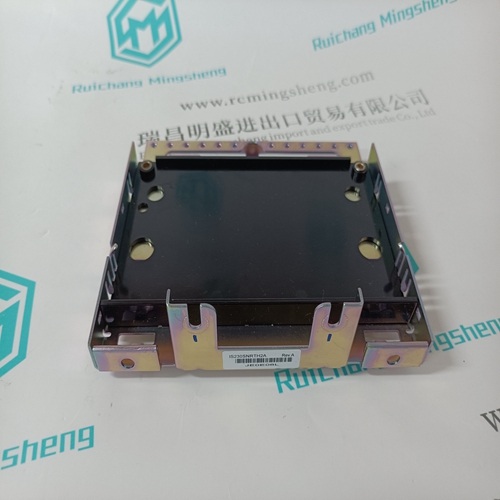

Home > Product > Gas turbine system > GE IS200TTURH1B interface module

GE IS200TTURH1B interface module

- Product ID: IS200TTURH1B

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GEIS200TTURH1Binterface module

- Get the latest price:Click to consult

GE IS200TTURH1B interface module

From the main measurement screen select “menu” and enter. Select “calibrate” and enter. 2. Enter “laser” and select the proper laser wavelength. Enter “average” and enter the desired averaging period. 3. Enter “factor” and apply the known laser power/energy. 4. Enter the “modify“ screen and adjust the factor until the power/energy reading on the screen equals the known power/energy. Press “save” and the power/energy calibration factor under “updated” will change accordingly.

Two main types of absorber surface are used in Ophir pyroelectric measuring sensors

1. Metallic type: The type with no suffix in the name have a partially reflective multilayer metallic coating which absorbs approximately 50% and whose absorption graph is shown in Graph 3 below. The metallic coating permits very high repetition rates, up to 25,000Hz as well as relatively high damage threshold.The relative readings at different wavelengths are fixed by the wavelength calibration curve stored in the sensor EEROM. When changing the calibration at one wavelength, the calibration at all other wavelengths will change proportionately

![]()

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/