Home > Product > Gas turbine system > GE WES5162 framework

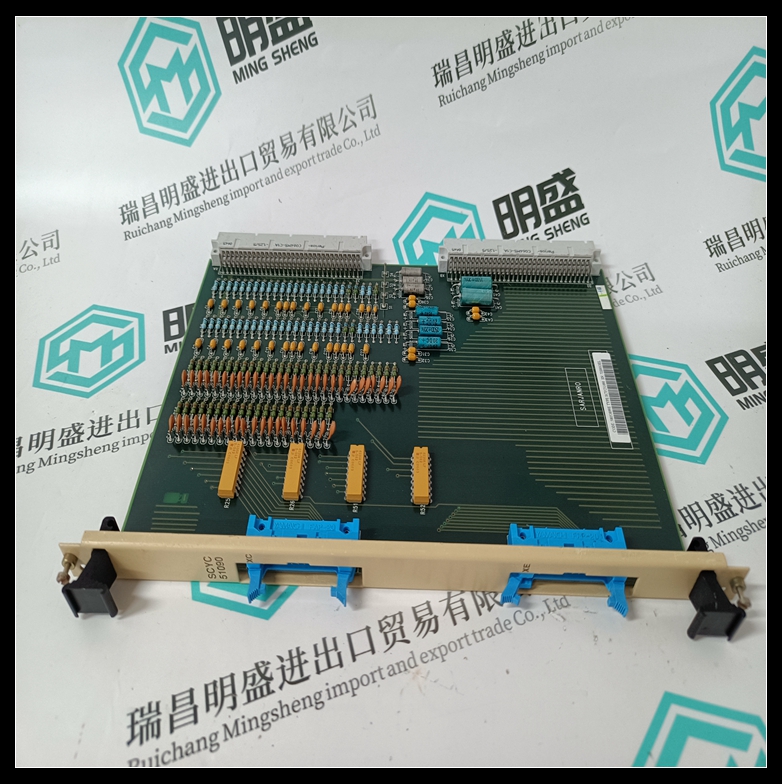

GE WES5162 framework

- Product ID: WES5162

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GEWES5162framework

- Get the latest price:Click to consult

GE WES5162 framework

Under the stated conditions, there will be no disturbance of digital I/O, encoder, or stepper operation. For analog signals, there may be momentary disturbances but there will be self-recovery when the noise subsides.Use care when wiring I/O devices to the MMC and when plugging in cables. Wiring the wrong device to the connector or plugging a connector into the wrong location could cause intermittent or incorrect machine operation.

As a general precaution

do not operate transmitters, arc welding equipment, or other high noise radiators within one meter of an enclosure that has the door open. Continue to equip inductive devices, if they are in series with a mechanical contact or switch, with arc suppression circuits. These devices include contactors, solenoids and motors. Shield all cables that carry heavy current near the system, using continuous foil wrap or conduit grounded at both ends. Such cables include power leads for high-frequency welders and for pulse-width-modulated motor drives.

![]()

Application industry

The products can be used in the following industries: power plant, paper making, steel, mining, rubber, water supply, cement, chemical industry, glass, printing Textile, machinery, plastics, coatings, medicine, hospitals, food, hotels, scientific research institutions

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/