Home > Product > DCS control system > CI532V05 3BSE007297R1 Control module

CI532V05 3BSE007297R1 Control module

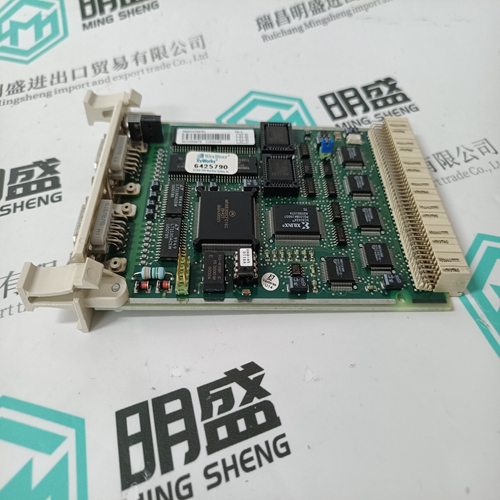

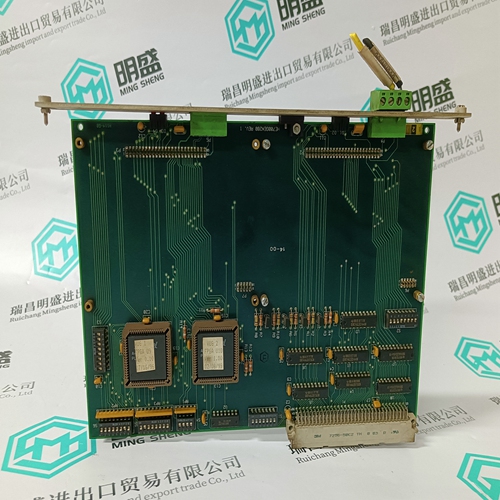

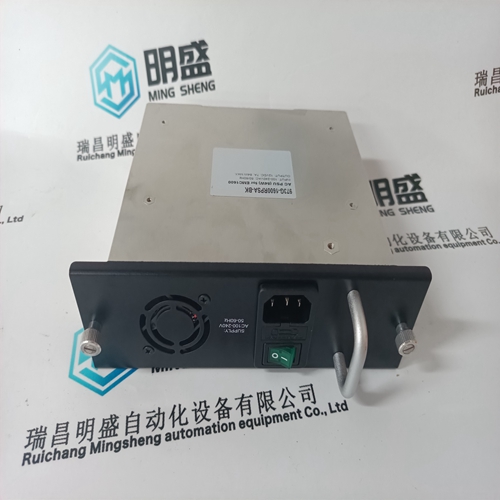

- Product ID: CI532V05 3BSE007297R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:CI532V05 3BSE007297R1 Control module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

CI532V05 3BSE007297R1 Control module

Honeywell offers multiple ExperionPKS controllers, ranging from embedded controller platforms with dedicated IO hardware to PC based control environments for supervisory control tasks or simulation. They all support one or more different network types to integrate the controllers with the ExperionPKS Server. They share a common Control Execution Environment (CEE) software infrastructure and a common builder tool. Together with the different station types, they form the ExperionPKS system. This specifications document provides details specifically related to the ExperionPKS C300 controller.In the following sections of this document the generic term “Controller” is used to reference various capacity and performance limits. Unless specifically noted differently, the following table defines what is meant by the term “Controller” when the specific controller type is not mentioned:Notes [1] for FTE Ethernet: 1. When any FTEB or C300-20ms is present in the FTE Community, or if EtherNet/IP™ (EIP) is being deployed by one or more C300s in the FTE Community, the limit is 200 FTE Nodes. 2. SCADA connected PLCs can still be connected via ControlNet/PCIC when C200s, C200Es, or C300s reside on the FTE Supervisory Control Network. 3. SCADA PLCs do not count as “Controllers” against this limit on FTE 4. 60 controllers in any combination of CEE based Controllers (C200, C200E, C300, UOC, vUOC) and/or CDAcapable controllers (Safety Managers (Max 20), and/or PMD Field Controllers (Max 25), and/or EHPMs (defined in Section 16.3 EHPM Capacities)

C300 Processing

The Figures below provides a simplified view of C300 Controller CPU usage. CPU in the C300 Controller is primarily used for three purposes – executing control strategies, communicating with the IO Links, and communicating with other entities outside the C300, such as peer nodes and displays.The key specification for C300 performance is as follows. • C300 – 50ms has 5500 XUs available for user Control, IO, and Communication needs • C300 – 20ms has 5000 XUs available for Control, IO, and Communications needs, although various operations and strategy configurations will contribute added XU weights to the calculations in this higher speed CEE (See note below)

Control requirements of a C300 are estimated in PUs, using a PU estimation spreadsheet similar to those used for C200 and ACE. The definition of a PU (see Section 1.4) does not change with the introduction of C300, because the PU definition is platform independent. C300 PU specifications are provided for the same set of typical module types (e.g. Small Analog Data Acquisition CM, Regulatory Control CM, Device Control CM, etc.) as already documented for C200 and ACE. PU specifications are not provided for Series C IO Modules and PM IO Modules, because the IO Module execution for these IO types is not part of CEE. Processing load attributed to the execution of Series C IO Modules and PM IO Modules is accounted for in the IO component of C300 CPU usage. 2.3.4.3 C300 IO Performance testing has determined that the following factors have the greatest influence on the amount of CPU used to support and communicate with IO. • IO Link 1 Type – PM IO, Series C IO, or None • IO Link 2 Type – PM IO, Series C IO, or None • IO Link 1 LUs – estimated from LU estimation sheet • IO Link 2 LUs – estimated from LU estimation sheet • Number of FTEB supported IO modules