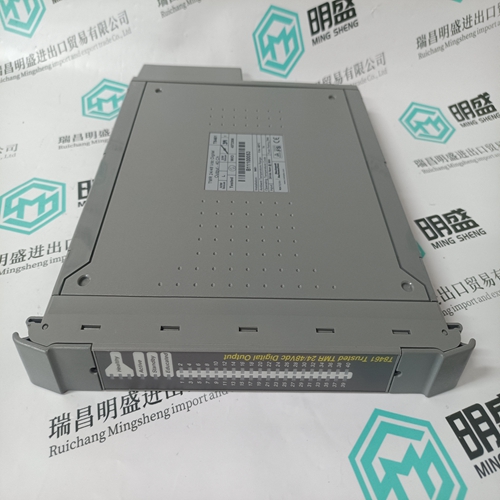

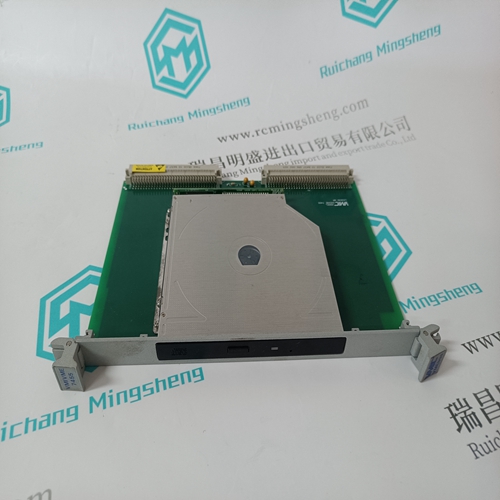

Home > Product > PLC programmable module > ICS TRIPLEX T8461 industrial module

ICS TRIPLEX T8461 industrial module

- Product ID: T8461

- Brand: ICS TRIPLEX

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ICS TRIPLEXT8461industrial module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ICS TRIPLEX T8461 industrial module

Parallel and analog I/Os Up to 8 internal opto-isolated inputs and outputs, 24 V DC, or external relay/transistor module (64 inputs, 64 outputs max.). Internal 15-bit analog output, external module for up to 4 analog inputs/outputs as option. Fieldbus interfaces PROFIBUS DP 12 Mbps or Modbus TCP. Ethernet interface 10/100 BASE-T Ethernet interface with integrated web server, WLAN as option. USB USB 2.0 host interface with optional IP65 connector for PC keyboard, scanner or USB stick. Security Powerfail safe storage of data, password protection, batterybacked realtime clock, remote diagnosis over Ethernet/ Internet possible. CPU and operating system 32-bit ARM processor, 266 MHz, 1.5 MB data memory, expandable. Linux based realtime multitasking operating system. Free programmability Comprehensive, PC-based program development and test environment. Programming with RTC WIN in ‘C’ in compliance with WELMEC software guidelines. Complete software development test and simulation possible on PC. Options RTC WIN IT8000E programming environment. PC COM+ Active X component for the communication with PC programs.Certifications – Directives: 2009/23/EC, 2004/108/EC, 2006/95/EC, 2004/22/EC – Standards: EN 45501, OIML R76-1, EN 61000-6-2, EN 61000-6-3, NAMUR NE21, EN 60950, OIML R51, OIML R61, OIML R107 – EC-approval as non-automatic weighing instrument, MID-approval as AGFI, checkweigher, automatic catchweighing instrument, weigh labeler, weigh-price labeler, discontinuous totalizer – NTEP-approval as non weighing instrument (in preparation) – ETL-certified in accordance with UL 60950-1 and CSA C22.2 no. 60950-1 – EMI compliance with FCC Part 15 – Ukraine: Approval as non-automatic weighing instrument

S200 SERIES DRIVES

Industry-Leading Performance In A Small Package Danaher Motion’s S200 brushless servo drives puts high performance servo technology into a full power range family with dc input and ac input family members. Particularly for lower power applications the S200 family provides a higher performing more robust option than was previously possible without having to compromise on reliability or package size. Coupling an S200 drive with Danaher Motion's AKM servomotor provides a complete servo control solution designed to excel in applications such as semiconductor fabrication, electronic assembly, packaging, medical, and woodworking equipment among others. Danaher Motion's S200 servo drives are the first all-digital industrial drives with a velocity loop bandwidth up to 800 Hz, offering unmatched system throughput and simplified tuning. High resolution (24 bit) feedback and high performance 3-5 kHz current loop bandwidth provide smooth motion and rapid start and stop action to optimize machine performance. Smart feedback and industry leading high bandwidth deliver fast and accurate "plug and play" commissioning by eliminating the need for servo loop tuning in most applications. Base S200 servo drives come standard with torque or velocity control, as well as with factory options that support the SynqNet motion network or add pre-settable Indexing with CANopen communications. The factory option cards also add interfaces to additional motor feedback devices such as Comcoder, 1 Vp-p Sin-Cos, EnDat 2.1, and EnDat 2.2 running in 2.1 compatibility mode. The option card EnDat interface accommodates single and multiturn absolute rotary or incremental and absolute linear encoders. The drives operate with AC (120/240 VAC) or DC (20-90 VDC) power sources and have current ratings from 1.5 ARMS continuous to 48 ARMS peak. Their compact footprint ranges from 1.1 in (28.7 mm) wide and 6.0 in (152.4 mm) tall to 3.8 in (94.6 mm) wide and 6.39 in (213 mm) tall with depths ranging from 3.9 in (100.8 mm) to 7.57 in (192.4 mm), allow them to fit into tight spaces. They are UL 508C recognized, CE marked, and conform to EN50178 and EN61800-3 standards.