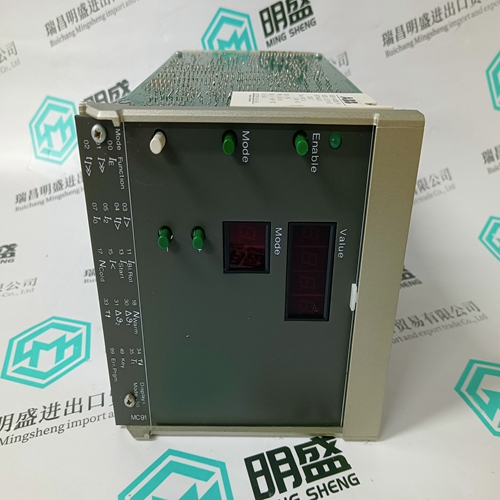

Home > Product > Servo control system > KOLLMORGEN CB06561 PRD-B040SSlz-62 Servo module

KOLLMORGEN CB06561 PRD-B040SSlz-62 Servo module

- Product ID: CB06561 PRD-B040SSlz-62

- Brand: KOLLMORGEN

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:KOLLMORGENCB06561 PRD-B040SSlz-62Servo module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

KOLLMORGEN CB06561 PRD-B040SSlz-62 Servo module

The original S200 family included lead in the soldering. Units manufactured after November 2007 are fully compliant with the EU RoHS environmental directive. The RoHS units also all have control logic version 3.0A or newer. See parameter VerLW. Separate "Keep Alive" control power input allows communications and diagnostics to continue during emergency stop conditions with no power to the motor. It also allows rapid recovery from emergency stops. Optically isolated inputs and outputs, positive locking connectors, and full fault protection promise long machine life and immunity to accidental damage. The single motor power or feedback cable option simplifies connectivity. All connectors and LED status indicators are easily accessible from the front of the drive. 1.1 MANUAL SCOPE This manual documents the S200 base drives and the S200 drives with the SynqNet motion bus option card installed. See the separate S200 Position Node User’s Guide and S200 Position Node Installation Guide part numbers M-SS-S2B-11 and M-SS-S2A11 respectively for S200 drives equipped with the Position Node option card.READ these instructions before connecting power. Damage can result from MISWIRING at the power terminals. DANGEROUS voltages are present on power input and motor output terminals. Only qualified personnel are permitted to transport, assemble, commission, and maintain this equipment. Properly qualified personnel are persons who are familiar with the transport, assembly, installation, commissioning and operation of motors, and who have the appropriate qualifications for their jobs.

BEFORE YOU BEGIN

Read all available documentation before assembling and using. Incorrect handling of products described in this manual can result in injury and damage to people and/or machinery. Strictly adhere to the technical information regarding installation requirements. Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has electrically charged components and hot surfaces. Control and power cables can carry a high voltage, even when the motor is not rotating. Never disconnect or connect the product while the power source is energized. After removing the power source from the equipment, wait at least 5 minutes before touching or disconnecting sections of the equipment that normally carry electrical charges (e.g., capacitors, contacts, screw connections). To be safe, measure the electrical contact points to each other and to electrical safety earth with a meter before touching the equipment. 2.2 UNPACKING AND INSPECTING Open the box and remove all the contents. Check to ensure there is no visible damage to any of the equipment. CAUTION Use proper procedures when handling electronic components to avoid damage to equipment. CAUTION Remove all packing material and equipment from the shipping container. Be aware that some connector kits and other equipment pieces may be quite small and can be accidentally discarded. Do not dispose of shipping materials until the packing list has been checked. NOTE Upon receipt of the equipment, inspect components to ensure that no damage has occurred in shipment. If damage is detected, notify the carrier immediately. Check all shipping material for connector kits, documentation, diskettes, CD-ROM, or other small pieces of equipment.