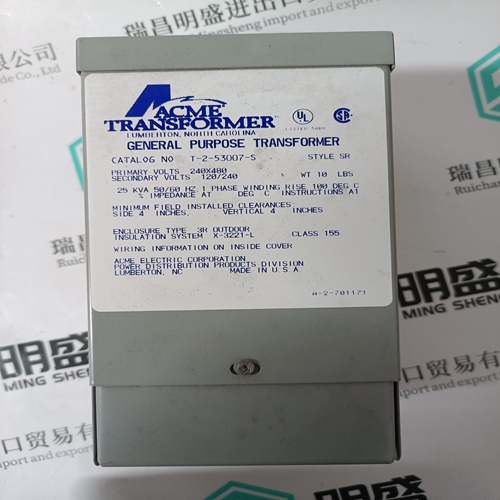

Home > Product > Robot control system > ACMETRANSFORMER T-2-53007-S transformer

ACMETRANSFORMER T-2-53007-S transformer

- Product ID: T-2-53007-S

- Brand: ACMETRANSFORMER

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ACMETRANSFORMERT-2-53007-Stransformer

- Get the latest price:Click to consult

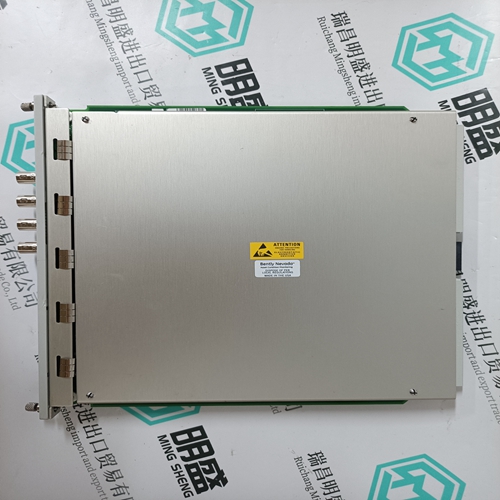

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ACMETRANSFORMER T-2-53007-S transformer

J1 – AC INPUT DRIVE POWER The S200 AC input drives are capable of direct line operation. All units are fully isolated and do not require external isolation transformers. The inrush current on the connection to the line is internally limited to a safe level for the drive. There are no voltage selection or ranging switches required to operate within the specified voltage input ranges. The S200 series drives are functionally compatible with all standard forms of three phase AC lines: Grounded neutral WYE Open-Delta Grounded Leg TEE NOTE The customer is responsible for supplying the appropriate fuses or circuit breakers in the J1 AC motor power lines to comply with local electrical codes. The control input power required is between 5 and 10 watts. The AC input motor power depends on output power and losses in the power stage. CAUTION Appendix G – Regulatory Information of this manual contains additional information needed to ensure regulatory compliance. On AC input drives with peak current < 18 Arms, J1 is a 9 pin pluggable connector (shown below). On larger AC input drives connections are to fixed terminal block TB1 that needs no mating connector. See wiring diagrams for full connection details.Mating Connector Information for S20260, S20250, S20360, S20560, S20660 Screw Terminal Connector 12 – 24 AWG Wire Range, Phoenix MSTB2,5/9-STF-5,08-BK OR Spring Cage Clamp Connector 12 – 24 AWG Wire Range, Phoenix FKC 2,5/9-SFT-5,08-BK OR Crimp

Chassis Screw PE Protective Earth

This chassis ground point must be connected to Protective Earth ground. The connection at the Protective Earth ground end must be hard wired (do not use a pluggable connection). A ground fault detector (RCD) cannot be depended on for safety. J1-2 or TB1-5 REGEN Connection for an optional regeneration power resistor to absorb regenerated energy from the motor. Models S20260 and S20360 typically use 36 Ω. S20660, S21260 typically use 12.5 Ω, and S22460 typically uses 8 Ω. Other values within the min to max resistance specification range can be used. Use a Wire wound resistor with 1500 VRMS isolation between terminals and case. Many applications do not require a regen resistor. If over-voltage faults occur during motor deceleration, then the more kinetic energy is being returned to the bus capacitors than they can handle. Connect the proper Ohmage 50 to 1000 watt power resistor from this terminal, to terminal J1-4 (+BUS) in order to eliminate the over-voltage faults. The power rating of the regen resistor depends on the amount of regenerated energy that needs to be dissipated. WARNING The regen input is not short circuit protected. The regen resistance MUST be within specified ranges to prevent damage to the drive. For example, S20260, S20360 drives must be between 25 to 50 Ω. NOTE For safety, either mount the external resistor on a grounded panel or wire it to a grounded connection. The terminals of the resistor MUST NOT be grounded. WARNING Wait 5 minutes after power is removed for the bus cap voltage to decay to a safe level before touching the regen resistor or wiring. Monitor the voltage on the bus caps with a voltmeter from +BUS (J1-4) to -BUS (J1-3).