Home > Product > DCS control system > DC732F 3BDH000375R0001 Input/output module

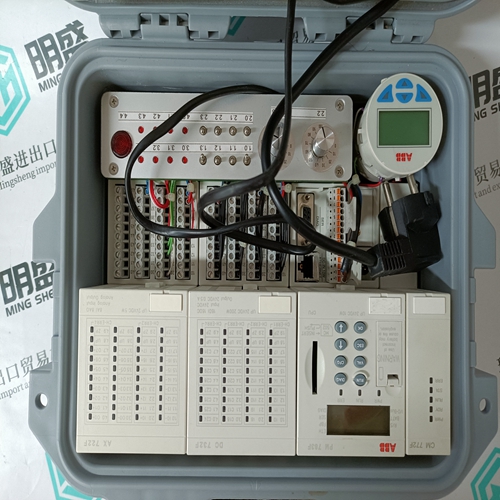

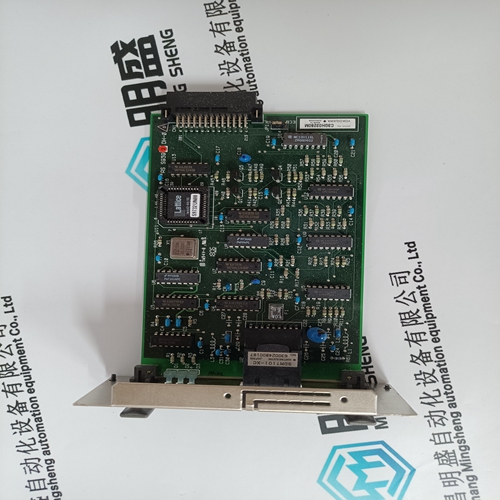

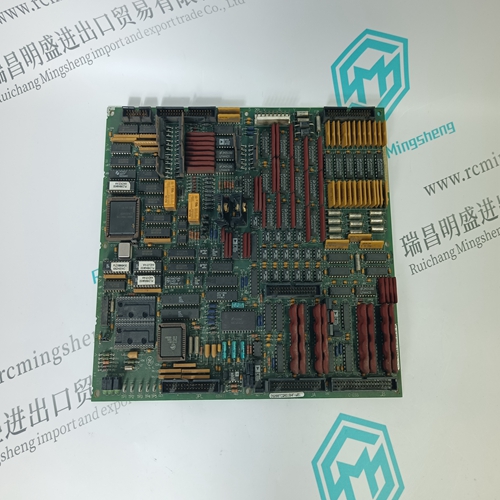

DC732F 3BDH000375R0001 Input/output module

- Product ID: DC732F 3BDH000375R0001

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:DC732F 3BDH000375R0001Input/output module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

DC732F 3BDH000375R0001 Input/output module

BUS ENERGY & POWER NUMERICAL EXAMPLES The energy flows in the drive bus are: • In - Motoring mechanical energy + Motor losses (motor accelerates). • Out - Regenerated mechanical energy – Motor losses (motor decelerates). • Out - Regenerated motor inductive energy (disable or fault). A.4.1 Min. External Bus Capacitance Inductance in AKM motors mated to S200s can be as high as 5 mH (line-to-line). The inductive energy stored in a 5 mH motor at 18 ARMS is calculated as: E winding = 0.75 x Inductance line-to-line x IRMS x IRMS = 0.75 x 0.005 henry x 18 RMS x 18 RMS = 1.2 joules The bus capacitor needed to absorb the regenerated energy (EREGEN) is sized using the general rule that the energy stored in the capacitor be a minimum of 5 * EREGEN. This limits the voltage increase on the bus due to regeneration to 10% of the DC value. Using this general rule to find the minimum bus capacitance for the motor in the above example (for simplicity, ignore that a fraction of regenerated inductive energy is dissipated in the motor): E bus cap = 5 x 1.2 joules = 6 joules E bus cap = 1/2 Cbus x DC voltage x DC voltage Assume the bus DC voltage is 75 volts Cbus = 2 x Ebus cap/(75 V x 75 V) = 2 x 6 joules/(75 V x 75 V) = 2,133 µF The internal S200 bus capacitance is 200 µf, which is less than 10% of the required capacitance for energy absorption.

Energy from Acceleration Time

The bus supply for a group of S200 drives must have enough total capacitance to handle brief, high-current bus transient flows (positive and negative) a few milliseconds without excessive bus voltage variation. The peak output power of a 6/18 ARMS DC S200 can be as high as 1.5 kW (1.5 kW = 18 ARMS x rt(2) x 60 V (emf + IR)). This is an energy flow of 3 joules for 2 ms or 15 joules for 10 ms. Mechanical energy is estimated by considering the load to be pure inertia and measuring the velocity transition times. A full torque acceleration or deceleration of an inertia load yields a triangle power pulse with an energy (in joules) half of the peak power (in watts) multiplied by the velocity ramp time (in seconds) from zero speed. Monitor the motor acceleration by mapping velocity and torque to DAC monitor pins (J4-14, 15), and then looking at them with a scope. Set DM1Map to VelFB and DM2Map to IFB. See the I/O Setting tab in S200Tools. At a peak power flow to the shaft of 1 kW = (25 A x 40 V EMF),The DC resistance of long motor power cables steals some of the available voltage when motor current is high. The principal effect of this is some reduction in peak motor power so acceleration and deceleration times can be longer. The cable resistance has no significant effect on lower speed torque or top speed. For most applications, the loss of performance is small with cables up to the maximum cable length specification. Do not operate an S200 DC Input Drive with long cables at the lower end of the bus voltage range because too much of the available voltage is stolen by the cable resistance. For S200 AC Input Drives, the DC resistance of the motor power cable is rarely an issue because the voltage drop across the resistance is usually a small fraction of the available nominal bus voltage. For S200 DC Input Drives with long cables and demanding dynamics, the 14 AWG cable is preferred over the 18 AWG cable. Cable voltage drop vs. cable length is shown in the table below.