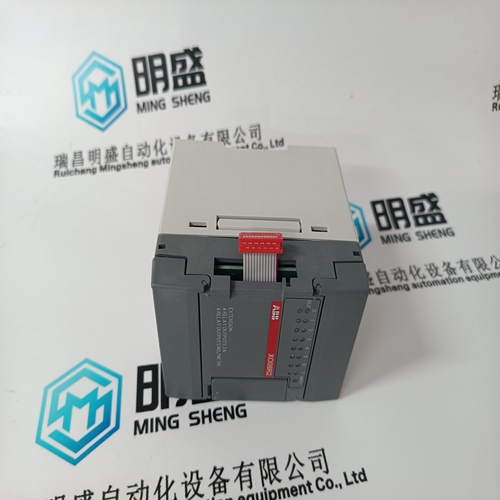

Home > Product > DCS control system > TU715F 3BDH000378R0001 Industrial control module

TU715F 3BDH000378R0001 Industrial control module

- Product ID: TU715F 3BDH000378R0001

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:TU715F 3BDH000378R0001Industrial control module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

TU715F 3BDH000378R0001 Industrial control module

A composite cable has both feedback and power wires within one overall cable jacket. One of the critical requirements for a composite cable is to provide a high degree of isolation between the power and feedback wires. With 240 VAC-connected drives the power wires can have up to 400 Vpeak-peak fast switching PWM waveforms that can couple to the feedback wiring. These coupled signals can cause communication errors between the Smart Feedback Device (SFD) and the drive.Danaher Motion has developed and sells a composite cable that has very good isolation between the power and feedback sections. It is strongly recommended that this raw cable be used for custom composite cable designs. Contact your Danaher Motion sales representative for additional information. If this cable does not meet your specifications, the following are some guidelines for custom composite cable development. Due to the complexity of modeling and understanding cable coupling, a new composite cable needs to be prototyped and tested to have confidence that it will be reliable. 1) Composite cable should have double concentric feedback shields – one shield within another. The raw composite cable that has been tested and is known to work well with the S200 has the following structure: double, concentric shields around the feedback wires, plus an outer shield around the whole cable (see diagram below). This type of raw cable is strongly recommended. Testing shows double, concentric, shielding is ten times better than single shielding at reducing coupling from the power wires to the feedback data wires.

Feedback Characteristic Impedance

There can be substantial capacitance between the power wires and adjacent feedback shield in a composite cable. Some of the PWM ampere level spikes tend to return in this adjacent shield, affecting the power stage voltage and current drive the feedback shield nearest to the power wires. In a single-shielded feedback cable this driven shield is also around the feedback data wires, so some coupling can occur. With double, concentric feedback shields, the driven shield is the outer of the two feedback shields, and interposed between the driven shield and feedback data wires is the inner feedback shield. Typically, the inner feedback shield is isolated from the connector shells and is connected to the return for the power supply powering the feedback device. NOTE A raw cable with two pairs of twisted, shielded feedback sections inside a composite cable is electrically the same as single feedback shielding. There may physically be two feedback shields in such a cable, but these shields are not concentric. There is only one shield between the power and feedback wires. Whereas the double, concentric feedback shields have two shields between the power and feedback wires. 2) SFD +5 and Gnd Resistance Spec To insure that the SFD +5 V at the SFD inside the motor is within specification, the voltage drop total in the SFD +5 V wire and SFD +5 V RTN wire must not be greater than 0.5 V at 150 mA. For this reason, a cable requirement is that the total resistance of the feedback SFD +5 V wire plus SFD +5 V RTN wire must be < 3.33 Ω (at 20° C). In practice, this means that for long cables, the AWG wire gage needs to be considered.