Home > Product > DCS control system > PM783F 3BDH000364R0001 Control processor

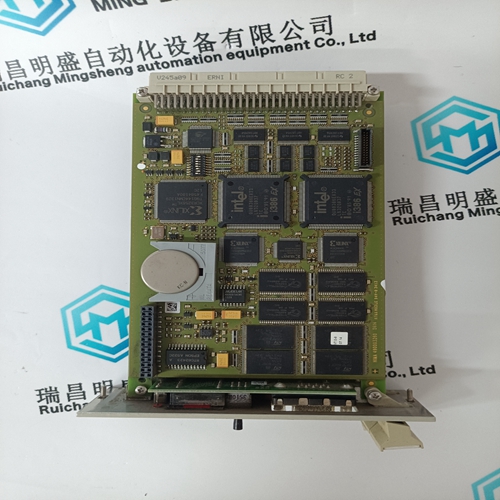

PM783F 3BDH000364R0001 Control processor

- Product ID: PM783F 3BDH000364R0001

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PM783F 3BDH000364R0001Control processor

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

PM783F 3BDH000364R0001 Control processor

Set Commutation Offset Angle:Zero the current command in the MEI MoCon utility as done in the Positive #3 step. Restore DPoles to its proper non-zero value. For linear motors this is usually 2 and for rotary motors must be the actual number of magnetic poles per revolution. For linear motors make sure AuxFBDivsor is set correctly to get commutation to work. See Chapter 8 Advanced Configuration for help with these NV parameters. Enable the drive while holding the motor. There should be 0 current command and there should be no force yet. Now apply a small (for example +1000 counts) current command in the MEI MoCon utility as described above. The motor should show a uniform force that doesn't vary as a function of magnetic cycle. Don't worry about the force direction. Now, try setting CommOff in S200 Tools to -120, 0, +120. Two of these settings will produce force in the wrong (negative) direction at one-half the expected force level. Use the value that produces positive direction force with the higher force level.

Summary

The S200 drive is now properly configured to run the non-catalog motor. Do an NVSave in the S200 Tools to save the settings, do a file save to save the settings for future reference, and document the working motor to drive wiring. If you would like to help others who might someday run the same motor email the setup file and wiring connections to your Danaher Motion products application engineer so they can share it with others.

NOTE: The above last step assumes that the motor was built conventionally and the Hall Commutation logic edges mechanically lined up with the motor line-line back EMF zero crossings. If the Hall commutation sensor has random alignment then you may need to make more careful measures to set CommOff to the optimal value which will give you the most force per amp of drive current.

AC Control Power

The use of 240 VAC, single-phase, nominal for control power results in the control voltage remaining within the drive control voltage specification (85 VAC to 265 VAC) during an F47 50% sag (deepest F47-specified sag). Powering the control with 240 VAC also maximizes the ride-through time for larger amplitude sags because more energy is stored in the control bus capacitor.

AC Bus Power

If three-phase 240 VAC is available for bus power, it provides much better F47 ridethrough than either single-phase 240 VAC or 120 VAC because F47 and F42 standards mandate that in a three-phase system, only one phase of the three phases is sagged at a time. If the AC S200 is powered by three-phase 240 VAC, it keeps its bus capacitors reasonably well-charged by pulling power from the one line-to-line voltage that does not sag. With single-phase AC bus power, a full torque acceleration of the motor to high speed during an F47-mandated voltage sag has the potential to drag the bus voltage down. If only the internal bus capacitors of a 3 A / 9 ARMS S200 are supplying the full 3 kW peak output power, the bus voltage sag rate is 13 V/ms.