Home > Product > PLC programmable module > BENTLY 125800-01 Monitor card

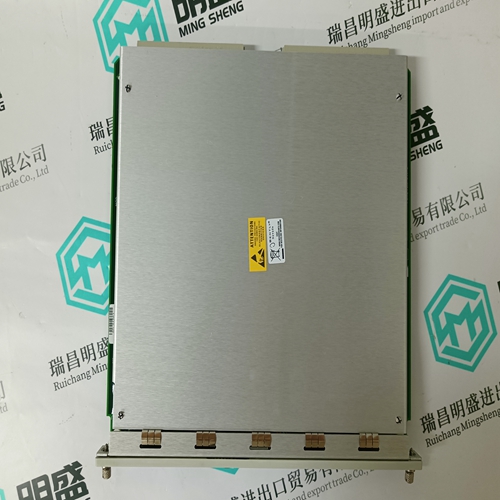

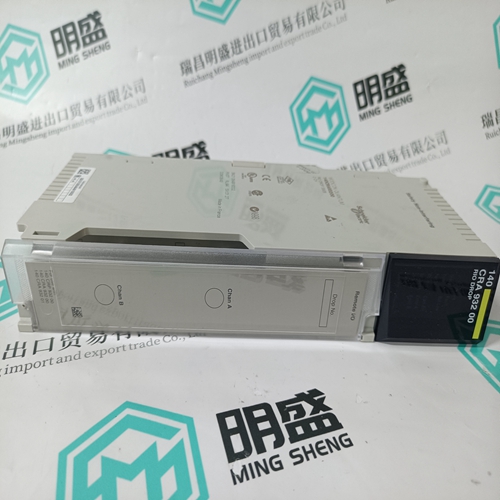

BENTLY 125800-01 Monitor card

- Product ID: 125800-01

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY 125800-01Monitor card

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

BENTLY 125800-01 Monitor card

To ensure compliance with the Low Voltage Directive and EN50178, following these requirements: Electronic drives contain electrostatic sensitive devices, that can be damaged when handled improperly. Qualified personnel must follow ESD protection measures. For example: wear grounded heel and wrist straps when contacting drive. The climatic conditions shall be in accordance with EN 50178 climatic class: Type B, temperature and relative humidity: Class 3K3. The drives shall be installed in an environment of Pollution Degree 2 or better. The S200 drives are not considered portable and are to be mounted in the intended manner in a motor/control cabinet having adequate strength and thickness with acceptable spacing for the end product classification accessible by qualified personnel only. The enclosure/cabinet shall meet at least the requirements of Protective Type IP2X according to 5.1 of EN 60529. If the top surface of the enclosure/cabinet is easily accessible it shall meet at least the requirements of the Protective Type IP4X. Care shall be taken to ensure that the larger device or enclosure that accommodates the built-in device provides protection against direct contact. The S200 drives may be erected in closed electrical operating areas if a protection against direct contact is available or assigned for by means of obstacles and/or a distance according to IEC 364-4-412.3 and IEC 364-4-412.4.

LOW VOLTAGE DIRECTIVE AND EN50178

Follow IEC 536-2 and IEC 1140 for installation protection against electric shock. Installation shall be performed in accordance with local electric codes, local accident prevention rules, EN 50178 and EN 61800-3. Never connect or disconnect any drive connectors or terminals while the power is switched on. Due to high leakage current, permanently install this drive (hard wired or fixed type). The PE connection shall be made by two separate protective conductors satisfying the requirements for protective conductors as given in 543 of HD 384.5.54 S1 between the earth ground and the PE terminal(s) on the drive, or by a protective conductor having a cross section of at least 10 mm2 Cu. The S200 drives are designed to Protective Class I. The discharge time for the bus capacitors may be as long as 5 minutes. After disconnecting the drive from the ac mains be sure to wait 5 minutes before removing the drive’s cover and exposing live parts. The finished installation shall comply with the requirements of the IEC 364-4-41 series of standards. The cables and leads (except the protective conductors) used in the erection of the S200 in an installation which are accessible for contact without opening or removing a barrier or are laid on extraneous conductive parts shall have double or reinforced insulation between the core and the surface or shall be surrounded by a metal screen having a satisfactory current-carrying capacity in the event of a short-circuit between the core and the screen.

When installing the S200 into its operating location,

it shall be ensured that any existing protective separation according to 5.2.18 of EN50178 is maintained throughout the entire length of the circuit in question. In installations the compliance for of the measures for protective separation shall be checked by visual inspection. Refer to Sections 1 and 4 of this manual for external fusing information. Motor cable shield must be connected to protective earth. During periods of extreme regeneration or excessively high input voltage the temperature of the regen resistor may exceed 70 °C. When using an external regen resistor, if regen cabling is accessible during normal machine operation, regen resistor cable should be rated at 300 Vac and shielded with shield connected to PE.

Consult the factory before using this product on a circuit protected by a residualcurrent-operated protective device (RCD). All covers shall be closed during operation. The S200 drives should be used within their specified ratings.

UL AND CUL CONFORMANCE

The S200 drives are UL and cUL Recognized to UL 508C under UL File number E137798. Consider the following points to ensure that final installation meets UL requirements: The drive should be used within its specified ratings. The drive should be mounted in the intended manner in an enclosure having adequate strength and thickness with acceptable spacing for the end product classification. The spacing from the exposed live-metal parts to the enclosure wall should be in accordance with the requirements for the overall equipment. These drives shall be used in a pollution degree 2 environment in order to comply with the spacing requirements of UL 840 and UL 508C. The UL temperature tests were done with a metal heat plate with overall dimensions, 6 in x 12 in x 1/8 in. The machine builder is responsible for ensuring adequate heat sinking capability in the final installation. The thermal protective device(s) provided integral to the motor drives were not evaluated by UL. The terminals are suitable for factory wiring only. These motor drives have not been evaluated to provide solid-state overload or over speed protection. The DC models were evaluated by UL for use with an isolated power supply rated no more than 150 V open circuit secondary voltage and 10 kVA secondary power. This combination shall be maintained to satisfy UL requirements.