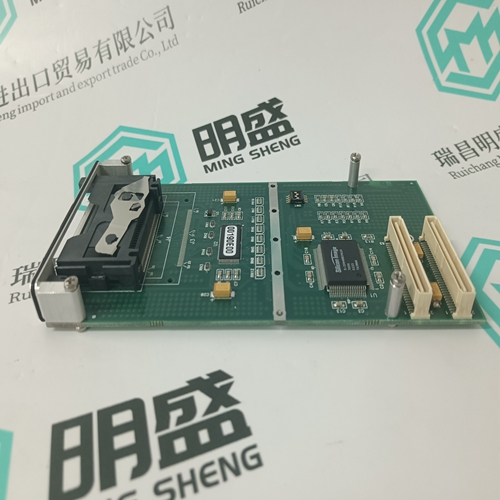

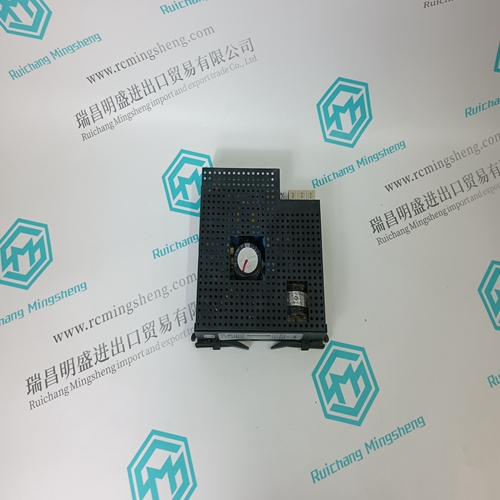

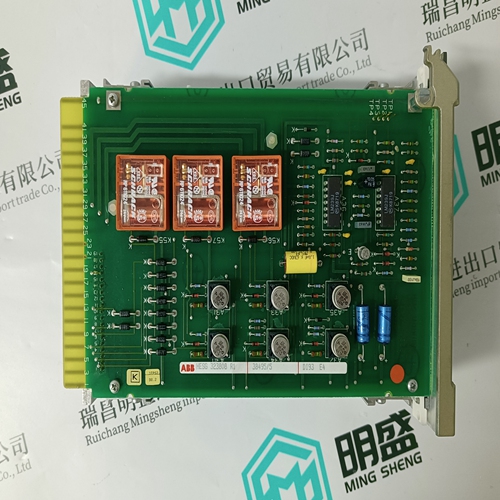

Home > Product > DCS control system > CI858K01 3BSE018135R1 processor module

CI858K01 3BSE018135R1 processor module

- Product ID: CI858K01 3BSE018135R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:CI858K01 3BSE018135R1processor module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

CI858K01 3BSE018135R1 processor module

Route wiring close to machine frame - It is a good practice to run wires along the machine frame (local ground) whenever practical, this couples some high frequency noise/signals that could otherwise be troublesome directly to the local ground. Remove paint from all drive, filter, and cable clamp mounting locations. Add clamp-on ferrites to cables – Adding clamp-on ferrites to noisy cables can reduce emissions by absorbing RF energy before it is radiated. Use the appropriate line filter – A line filter is required for CE applications, more information on line filter selection can be found in D.10 Add a balun to the motor power cable – adding a balun in series with the U, V and W phases of the motor power cable can attenuate both conducted and radiated emissions. Ensure that cables shields have a good RF ground – more information on this can be found in D.10.

Improve Machine EMC Performance

Use Danaher Motion cables – Danaher Motion cables have been designed with EMC considerations in mind. Because subtle differences in cable construction can cause dramatic changes in EMC performance use of Danaher Motion's motor power and feedback cables is recommended. When joining or splicing sections of cable, be sure to maintain the integrity of the cable shield along the entire length of the finished cable. Separate cables according to type - AC Mains input, motor power and signal cables should be separated from each other by at least 100 mm (4 in) to avoid cross coupling between them. If cables of different types have to cross, they should do so at a 90° angle.

AC MAINS CONDUCTED EMISSIONS

Line Filter To meet the CE-conducted EMC requirements, an external line filter (in series with the AC mains) is necessary. It is the responsibility of the machine builder to choose filter(s) appropriate for the application. Danaher Motion is willing to assist in this choice. Often, the decision is made to filter the machine as a whole instead of filtering the individual drives. Mount the line filter as close as possible to the point where incoming power enters the machine/cabinet. Locate the drive(s) as close as possible to the line filter. To provide maximum high frequency filtering, remove any paint from between the filter, the drive and the conductive surface, ground plane to which they are bonded. For maximum benefit, separate input wiring to the line filter and output wiring from the line filter from each other. During CE testing, multiple line filters were qualified for use with 50 m motor and feedback cables to represent worse-case, conducted emissions compliance. The below lists filters used during CE testing. Match filter rating to drive input ac ratings for proper combinations. Corcom 6EQ1 (single phase) Corcom 36FCD10 (three phase) MTE RF30006-4 (three phase) Schaffner FN258-7, FN258-16, FN258-30, FN3258-16, FN3258-30 (three phase)

Motor Power Cable Filtering

In typical applications, the S200 drives do not require additional filtering in the motor leads. Machines with many drives and long motor power cables may require an external balun in series with the power motor power cable to reduce the machine’s conducted emissions. Additional information can be found in Pacific Scientific Application Notes 106 (Reducing Motor Drive Line Noise) and 107 (Reducing Motor Drive Radiated Emissions).

Current Rating 60 A sinewave pk (42 ARMS) 5 sec 20 A sinewave pk (14 ARMS) cont Inductance 340 µh nominal Energy Rating 7,200 µJ nominal Resistance 0.021 Ω nominal Gap 10 mil Ground Cable Shields The Motor Power (J2 or TB1), Feedback (J3), Command I/O (J4), and Serial Port (J5) cables must be shielded and the shields should be connected to PE. The safety PE connection can be made through connector pin or shell.

All cables used with the S200 drives should be shielded with the shields connected to PE. Dangerous voltages, resulting from cable capacitance, exist on some cable shields if the shields are not connected to PE ground. Avoid Crosstalk CAUTION To avoid the risk of crosstalk, keep the motor and feedback cables away from sensitive signal cables (i.e., telephone and intercommunication lines). Shield all cables used with the S200 drives with the shields connected to PE.