Home > Product > Gas turbine system > GE IC660TBD024 Industrial automation components

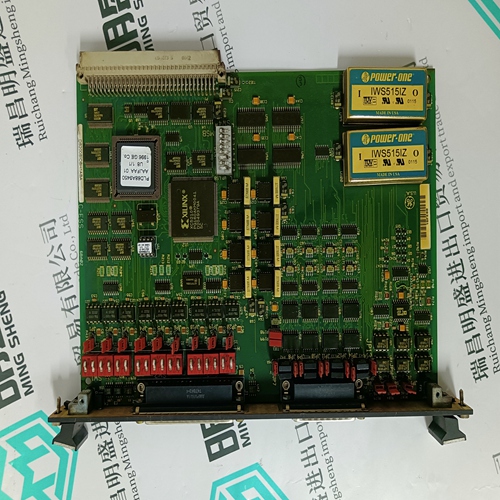

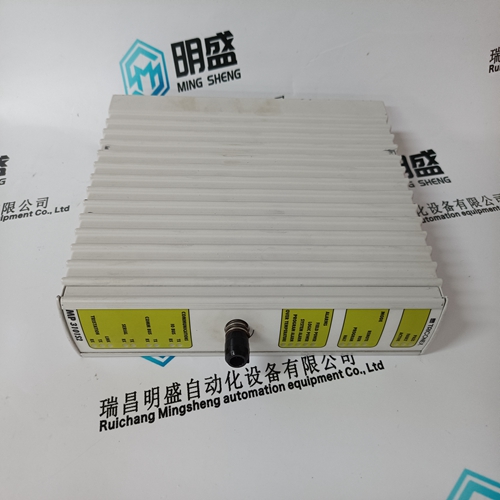

GE IC660TBD024 Industrial automation components

- Product ID: IC660TBD024

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEIC660TBD024Industrial automation components

- Get the latest price:Click to consult

GE IC660TBD024 Industrial automation components

GE IC660TBD024 Industrial automation components

a. Visual and mechanical inspection. The fault protection subsystem should be visually inspected every 2 months and mechanically inspected every 12 months per NETA guidelines. (1) Inspect all electrical/electronic equipment for safety grounding conductors (green wire). Check to see that sizes conform to all designated requirements. (2) Spot check all green wire connections to see that they are tight and free of corrosion. (3) Check inside equipment, switch boxes, and distribution panels to see that the white wire (neutral) is not grounded at these locations. (4) Check the grounding connection at the first service disconnect to make sure it is tight and free of corrosion. (5) Generally check the electrical supporting structures for looseness in joints or bonds and evidence of corrosion.

Main business of the company

1.Focus on DCS, PLC, robot control system and large servo system. Main products: various modules/cards, controllers, touch screens, servo drives.

2.Advantages: We supply imported genuine products, professional off production accessories, fast delivery and accurate delivery.

3.Main brands: ABB, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog, PROSOFT, etc

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/