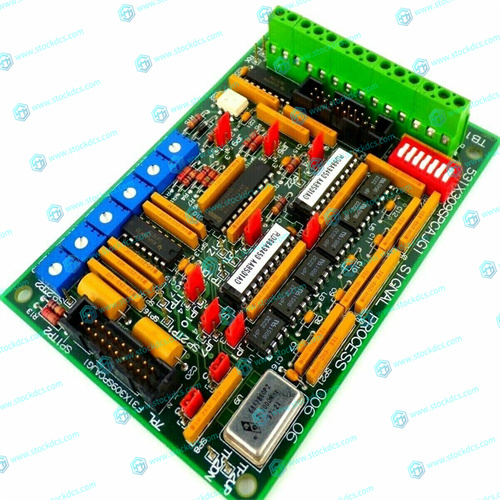

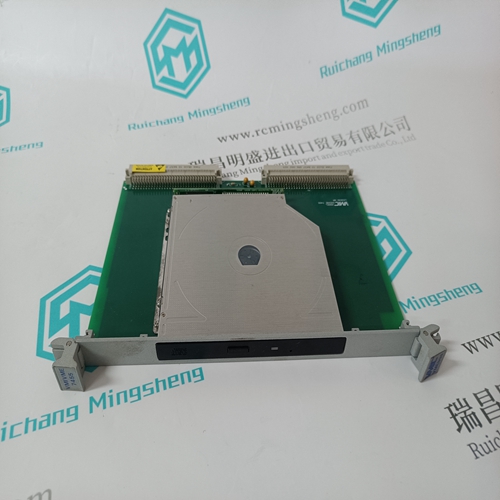

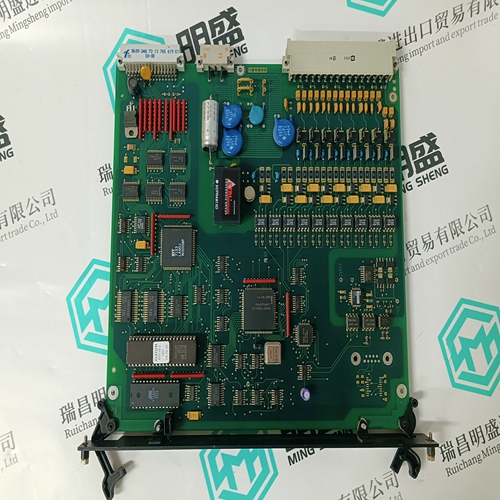

Home > Product > Gas turbine system > GE 531X309SPCAJG1 Variable monitor module

GE 531X309SPCAJG1 Variable monitor module

- Product ID: 531X309SPCAJG1

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GE531X309SPCAJG1Variable monitor module

- Get the latest price:Click to consult

GE 531X309SPCAJG1 Variable monitor module

GE 531X309SPCAJG1 Variable monitor module

Signal reference subsystems Proper maintenance of the signal reference subsystems requires the following inspection and testing activities be performed at regular intervals. a. Visual and mechanical inspection. The signal reference subsystem should be visually inspected every 2 months and mechanically inspected every 12 months per NETA guidelines. (1) Inspect connections to equipment signal ground terminals and equipotential plane for looseness and corrosion. Apply corrective measures. (2) Check to see if any new equipment has been added or relocated since the last inspection. If so, check interconnecting cables for conformance with the requirements.

Main business of the company

1.Focus on DCS, PLC, robot control system and large servo system. Main products: various modules/cards, controllers, touch screens, servo drives.

2.Advantages: We supply imported genuine products, professional off production accessories, fast delivery and accurate delivery.

3.Main brands: ABB, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog, PROSOFT, etc

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/