Home > Product > PLC programmable module > ILS1B853S1456 motor

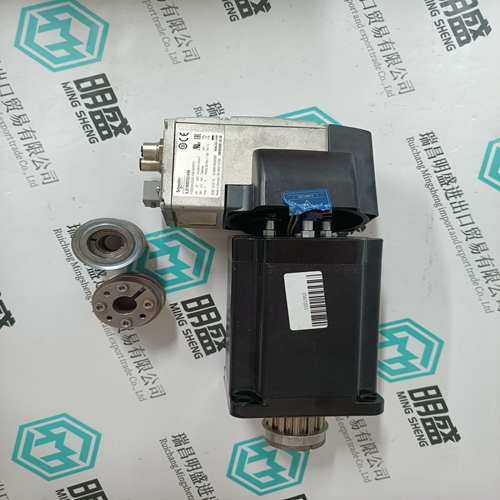

ILS1B853S1456 motor

- Product ID: ILS1B853S1456

- Brand: 140PLC

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ILS1B853S1456motor

- Get the latest price:Click to consult

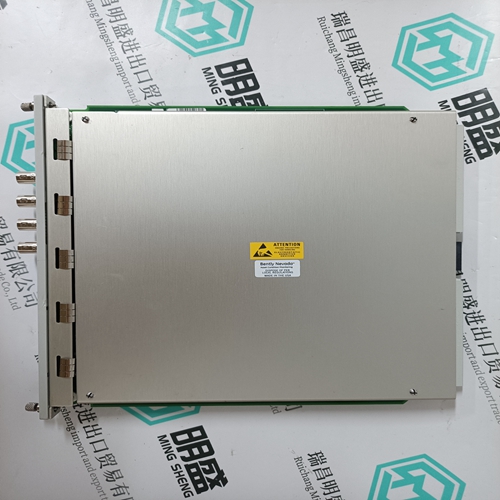

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ILS1B853S1456 motor

Racks with Internal Barriers installed require a 3500/04-01 Internal Barrier Earthing Module to provide the IS Earth connection to the 3500/05 rack. This earthing module requires a dedicated rack position. The 3500/93 System Display A01 System Face Mount option is incompatible with the 3500/05 Mini-rack. The 3500/05 mini-rack is not available in the Bulkhead Mount option. The 3500/06 weatherproof housing is not compatible with the 3500/05 Bulkhead Mount option. When using a 3500 mini-rack in an EIA rack, a 144863-01 19-inch EIA Adapter Panel is required. The 3500 mini-rack requires Version 2.70 or later of the 3500/01 Software. Ordering Information For the detailed listing of country and product specific approvals, refer to the Approvals Quick Reference Guide (108M1756) available from

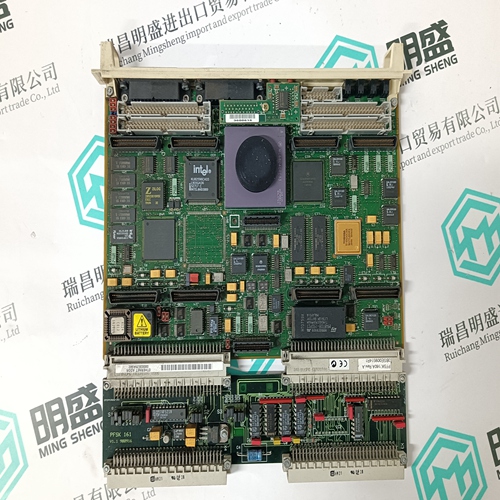

Technical specifications

The module can be plugged into either the central frame or the expansion frame. It supports CAN 2.0A (11 bit) and CAN 2.0B (29 bit) frames with a freely selectable transfer rate from 10 kbps to 1 Mbps. The CAN 300 PRO can send and receive CAN telegrams in Layer 2 mode. In the CANopen master mode, the data of the CANopen slaves can be processed as a process image table in the PLC. Use as a CANopen slave is also possible. For standard applications, such as motor control with CANopen, application examples are available. In addition, handling blocks for the SAE J1939 protocol are available. There are 16 freely settable timers available in the CAN 300 PRO. Each timer can trigger a freely programmable CAN telegram. This means the synchronous protocols widely available in drive and servo control are easy to implement using the CAN 300 PRO. A DIP switch for setting the transfer rate and station address facilitates commissioning. An optional Micro memory card stores the project. In this way, replacement of the parameterization or the module during servicing can be carried out quickly. 6 LEDs indicate the operating status of the module. There is a USB interface for diagnostics and parameterization. The CAN 300 PRO also works in the extended ambient temperatures of -25 °C to +60 °C. A USB programming cable is included in the delivery.

DESCRIPTION

The MicroLYNX is a powerful machine control system in te grat ing a bi po lar microstepping driv er and ex pand able pro gram ma ble controller into a com pact panel mounted assembly. Available in two out put power ranges, MicroLYNX fi ts a va ri ety of mo tor sizes. Fea tures such as +5 to +24 VDC isolated I/O, mul ti ple com mu ni ca tion types and nu mer ous ex pan sion op tions make the MicroLYNX an effective and powerful ma chine con trol solution. Optional dif fer en tial I/O modules give the MicroLYNX the ca pa bil i ty of driving two additional axes sequentially or allowing electronic gearing by following a rotary or lin ear axis, or out put ting a second clock at an elec tron i cal ly controlled ra tio. The MicroLYNX provides for two fully independent com mu - ni ca tion ports. It will ac cept com mands from either port and di rect out put to ei ther as well. A sys tem could be confi gured to use COMM port one to com mu - ni cate to a host PC or PLC while the second com mu ni cates with an op er a tor in ter face or ad di - tion al MicroLYNX.

EXPANSION MODULES

Up to three expansion modules can be added to fi ll the MicroLYNX expansion slots. Module combinations are limited to 2 Analog Input/ Joystick Modules, 2 Analog Output Modules, 1 Twelve Channel I/O Module, up to 2 HighSpeed Dif fer en tial I/O Mod ules, and up to 3 General Pur pose I/O Modules per system. By simply removing two screws on the MicroLYNX side cover, ex pan sion modules can be added, removed or reconfi gured. No additional hardware is required. Mod ules snap easily into place, making even fi eld change quick and easy.