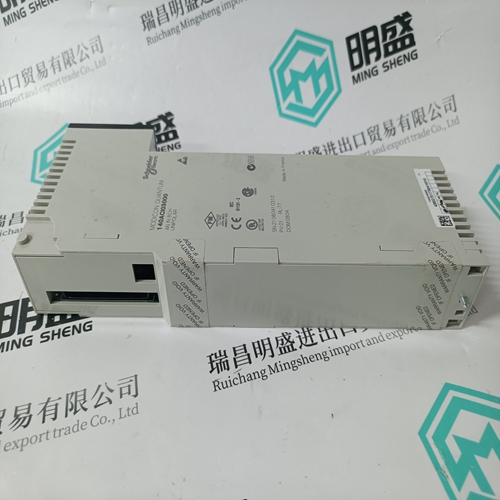

Home > Product > PLC programmable module > 140ACI03000 Output module

140ACI03000 Output module

- Product ID: 140ACI03000

- Brand: 140PLC

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:140ACI03000Output module

- Get the latest price:Click to consult

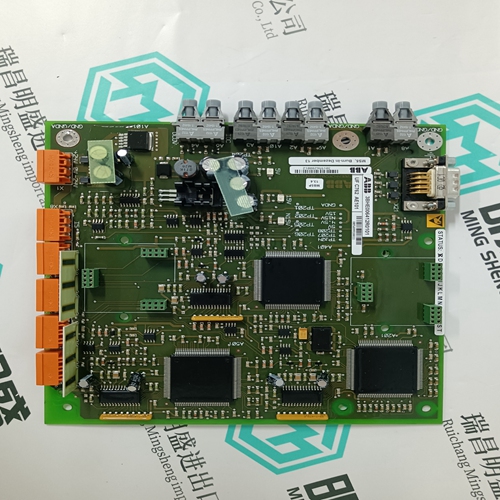

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

140ACI03000 Output module

The following should be observed with electrical drive and filter components: Wait five (5) minutes after switching off power to allow capacitors to discharge before beginning to work. Measure the voltage on the capacitors before beginning to work to make sure that the equipment is safe to touch. ⇒ Never touch the electrical connection points of a component while power is turned on. ⇒ Install the covers and guards provided with the equipment properly before switching the equipment on. Prevent contact with live parts at any time. ⇒ A residual-current-operated protective device (RCD) must not be used on electric drives! Indirect contact must be prevented by other means, for example, by an overcurrent protective device. ⇒ Electrical Components with exposed live parts and uncovered high voltage terminals must be installed in a protective housing, for example in a control cabinet.

Electric Shock by Protective Low Voltage

All connections and terminals with voltages between 0 and 50 Volts on Rexroth Indramat products are protective low voltages designed in accordance with international standards on electrical safety. WARNING High electrical voltage due to wrong connections! Danger to life, bodily harm by electric shock ! ⇒ Only connect equipment, electrical components and cables of the protective low voltage type (PELV = Protective Extra Low Voltage) to all terminals and clamps with voltages of 0 to 50 Volts. ⇒ Only electrical circuits may be connected which are safely isolated against high voltage circuits. Safe isolation is achieved, for example, with an isolating transformer, an opto-electronic coupler or when battery-operated.

Protection Against Dangerous Movements

Dangerous movements can be caused by faulty control of the connected motors. Some common examples are: • improper or wrong wiring of cable connections • incorrect operation of the equipment components • wrong input of parameters before operation • malfunction of sensors, encoders and monitoring device • defective components • software or firmware errors Dangerous movements can occur immediately after equipment is switched on or even after an unspecified time of trouble-free operation. The monitoring in the drive components will normally be sufficient to avoid faulty operation in the connected drives. Regarding personal safety, especially the danger of bodily injury and material damage, this alone cannot be relied upon to ensure complete safety. Until the integrated monitoring functions become effective, it must be assumed in any case that faulty drive movements will occur. The extent of faulty drive movements depends upon the type of control and the state of operation.

Dangerous movements!

Ensure personal safety by means of qualified and tested higher-level monitoring device or measures integrated in the installation. Unintended machine motion is possible if monitoring device are disabled, bypassed or not activated. ⇒ Pay attention to unintended machine motion or other malfunction in any mode of operation. ⇒ Keep free and clear of the machine’s range of motion and moving parts. Possible measures to prevent people from accidentally entering the machine’s range of movement: - use safety fences - use safety guards - use protective coverings - install light curtains or light barriers ⇒ Fences and coverings must be strong enough to resist maximum possible momentum, especially if break off parts can fly into the environment.