Home > Product > DCS control system > FBM219 RH916RH Thermal resistance module

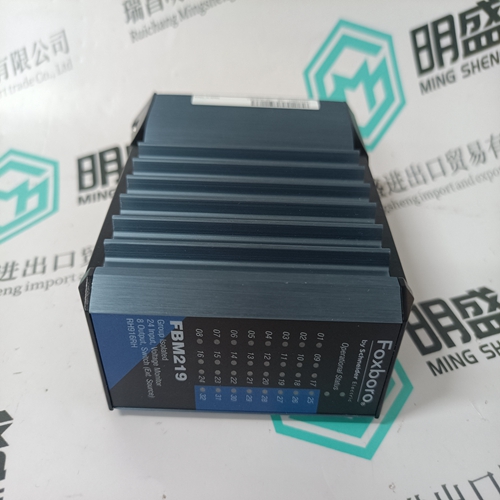

FBM219 RH916RH Thermal resistance module

- Product ID: FBM219 RH916RH

- Brand: FOXBORO

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:FBM219 RH916RHThermal resistance module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

FBM219 RH916RH Thermal resistance module

Technical data • The following data is provided for general applications. If you require data that is more relevant to your specific application, please contact us or your local sales office. • Additional information (certificates, special tools, software,...) and complete product documentation can be downloaded free of charge from the website (Downloadcenter)

The electromagnetic flowmeters are designed exclusively to measure the flow and conductivity of electrically conductive, liquid media.

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation. If the device is not used according to the operating conditions (refer to chapter "Technical data"), the intended protection could be affected. This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in industrial environment. There may be potential difficulties in ensuring electromagnetic compatibility in other environments, due to conducted as well as radiated disturbances

Installation specifications

The following precautions must be taken to ensure reliable installation. • Make sure that there is adequate space to the sides. • The device must not be heated by radiated heat (e.g. exposure to the sun) to an electronics housing surface temperature above the maximum permissible ambient temperature. If it is necessary to prevent damage from heat sources, a heat protection (e.g. sun shade) has to be installed. • Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat exchanger. • Do not expose the signal converter to intense vibrations. The measuring devices are tested for a vibration level as described in the chapter "Technical data".

Mounting of the compact version

Turning the housing of the compact version is not permitted. The signal converter is mounted directly on the flow sensor. For installation of the flowmeter, please observe the instructions in the supplied product documentation for the flow sensor.

Remarks for sanitary applications • To prevent contamination and dirt deposits behind the mounting plate, a cover plug must be installed between the wall and the mounting plate. • Pipe mounting is not suitable for sanitary applications! Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools in compliance with the applicable occupational health and safety directives.Fasten the mounting plate to the pipe with standard U-bolts, washers and fastening nuts. 2 Screw the signal converter to the mounting plate with the nuts and washers.