Home > Product > DCS control system > CS31 Bus optical transceiver

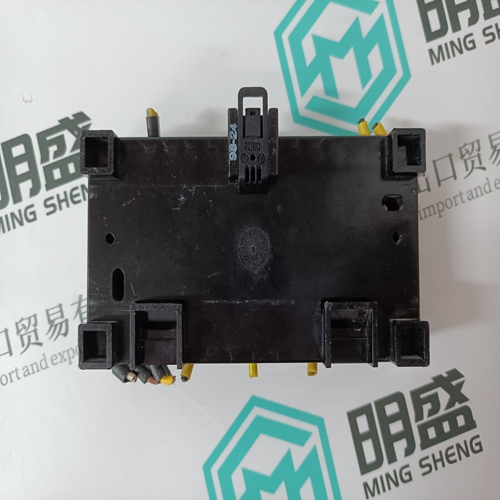

CS31 Bus optical transceiver

- Product ID: CS31

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:CS31Bus optical transceiver

- Get the latest price:Click to consult

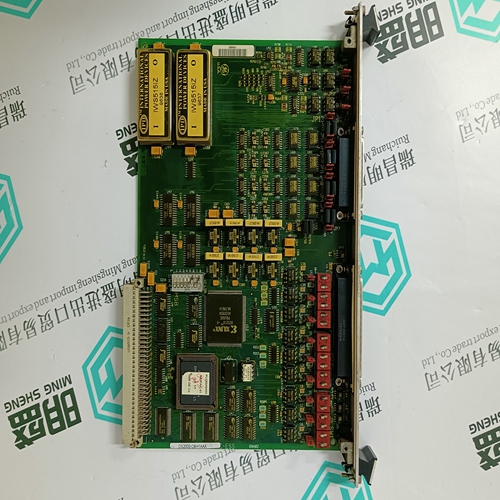

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

CS31 Bus optical transceiver

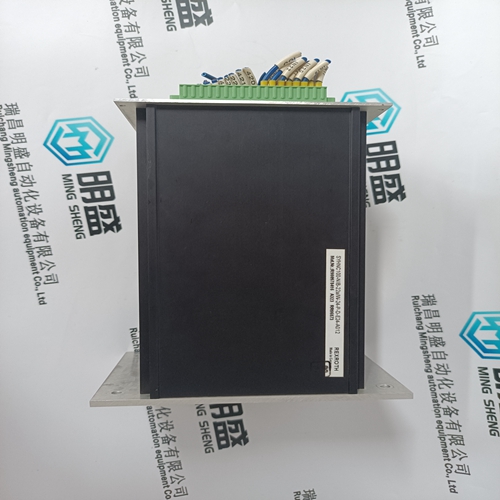

Personnel qualifications The activities described in this documentation require basic knowledge of electrics and hydraulics as well as knowledge of the associated technical terms. To ensure safe usage, these activities may therefore only be carried out by qualified personnel or under the direction and supervision of qualified personnel. Qualified personnel are those who, due to their professional training, knowledge and experience as well as their knowledge of relevant regulations, can assess work assigned to them, recognize potential hazards and institute appropriate safety measures. Qualified personnel must observe relevant specialist rules and have the required expertise. With regard to hydraulic products, specialist knowledge means, for example: • Ability to read and completely understand hydraulic circuit diagrams, • complete understanding in particular of interrelationships with regard to safety equipment and • knowledge of the function and structure of hydraulic components.

General safety instructions

• Observe valid regulations for accident prevention and environmental protection. • Observe the safety regulations and rules of the country where the product is used/ operated. • Use Rexroth products only in technically perfect condition. • Observe all notes given on the product. • Persons who install, commission, operate, demount or maintain Rexroth products must not consume any alcohol, drugs or pharmaceuticals that may affect their ability to respond. • Only use accessory and spare parts approved by the manufacturer in order to rule out personnel hazards arising from unsuitable spare parts. • Adhere to the technical data and ambient conditions provided in the product documentation. • If unsuitable products are installed or used in safety-relevant applications, unintended operational states can occur in these applications, which can cause personal injury and damage to property. Therefore, use the product only in safety-relevant applications such as in explosion protection areas or in safetyrelated parts of a control (functional safety), if this use is expressly specified and permitted in the documentation. • You may commission the product only when it has been established that the final product (for example, a machine or system), in which the Rexroth products are installed, complies with national regulations, safety regulations and standards relevant for the application.

Hazardous movement!

Risk of injury due to incorrect activation of the pump control by the control electronics and resulting unforeseeable machine movements. ▶ Only operate the control electronics in conjunction with the pump control specified in the type code. ▶ If persons have to enter the hazard zone while the control is active, provide superordinate monitoring functions or measures for personal safety at system level. The plant manufacturer/user must rate and dimension these measures on the basis of a risk and failure analysis according to the specific situation on site. The safety regulations valid for the system must be taken into account for this. The control electronics emits interference to other electronics within the permitted limit values. This can cause malfunction in the control process. ▶ Only use electronics below the EMC limit values or provide appropriate shielding. The control electronics VT-VPCD responds to electromagnetic interference from non-shielded, improperly installed or wrongly connected cables. If the limit values given in the data sheet are exceeded, malfunction or uncontrolled movements are possible.