Home > Product > DCS control system > TRICONEX 8312 Industrial card

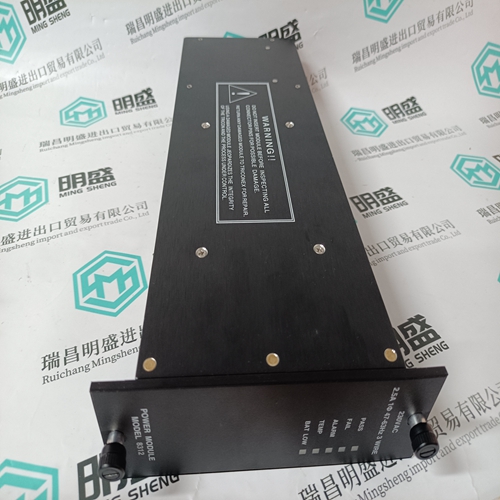

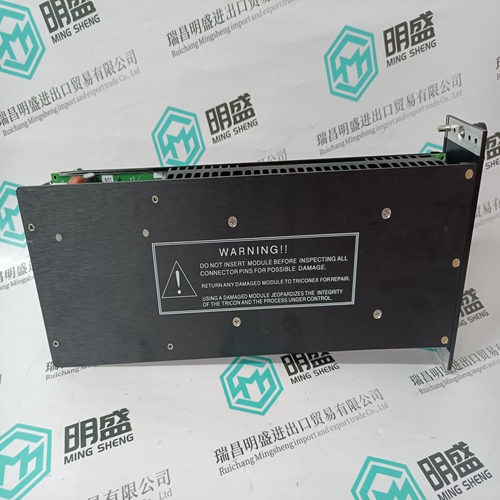

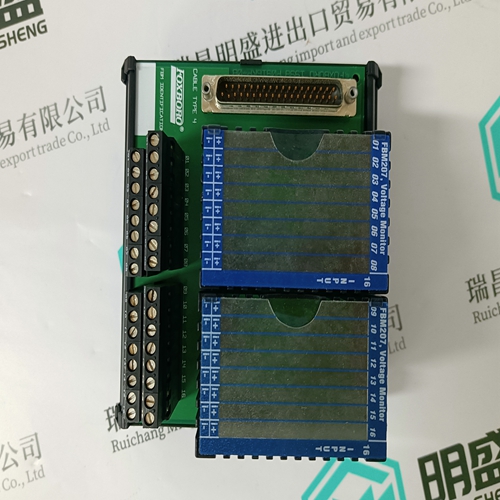

TRICONEX 8312 Industrial card

- Product ID: 8312

- Brand: TRICONEX

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:TRICONEX 8312Industrial card

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

TRICONEX 8312 Industrial card

Adhere to the limit values specified in the data sheet, use only electronics below the EMC limit values or provide proper shielding. Electrostatic processes, an inadequate grounding concept or missing equipotential bonding can lead to damage to the electronics and hence cause malfunction or uncontrolled movements of the machine. ▶ Ensure proper grounding and provide equipotential bonding. Using the product outside the given IP protection class can result in short-circuit and malfunction and can therefore cause uncontrolled machine movements. ▶ Only use the product within the IP protection class and under ambient conditions as given in the data sheet. The control electronics VT-VPCD itself does not include safety functions for personal safety and is therefore no safety-relevant component. The control electronics merely serves to generate electrical functions of the pump controls. ▶ Provide safety functions for personal safety separately. ▶ Avoid contact with salt-containing environments and adhere to the ambient conditions specified in the data sheet. High pressure! Risk of injury! ▶ Depressurize the relevant system section before carrying out any work on the control electronics.

High electric voltage due to incorrect connection!

Danger to life, risk of injury through electric shock. ▶ Only connect devices, electrical components and lines which feature protective extra low voltage (PELV) to connections or terminals having voltages from 0 to 50 Volt. ▶ Only connect voltages and power circuits that feature safe isolation from dangerous voltages. Safe electrical isolation can be achieved for example with isolating transformers, safe optocouplers or mains-free battery operation. High voltage! Risk of injury. ▶ Wire or plug in the control electronics VT-VPCD only when it is disconnected from the power supply. Lightning! Risk of uncontrolled machine movements. ▶ An inadequate grounding concept or missing equipotential bonding can lead to damage to the electronics. Ensure equipotential bonding for the device. Failures and defects in the control current circuits or the energy supply! Risk of uncontrolled machine movements. ▶ Ensure safety in accordance with EN ISO 13849 or IEC 62061

Hot surfaces!

Risk of burning. System parts can heat up during operation. ▶ Let system parts cool down before touching them or wear protective gloves. Fault currents and short-circuits! Reduced safety and malfunction. ▶ The environment must be free from conductive contamination (acids, lyes, corrosive agents, salts, metal vapors, etc.) and the device must not be exposed to them. Generally, rule out deposits according to protection class IP 65.The warranty is valid exclusively for the configuration delivered. • Warranty claims will be rejected in the case of improper installation, commissioning and operation as well as in the case of use not in accordance with the intended purpose and/or improper handling.