Home > Product > PLC programmable module > BENTLY 1900/65A-01-02-01-00-00 Monitor module

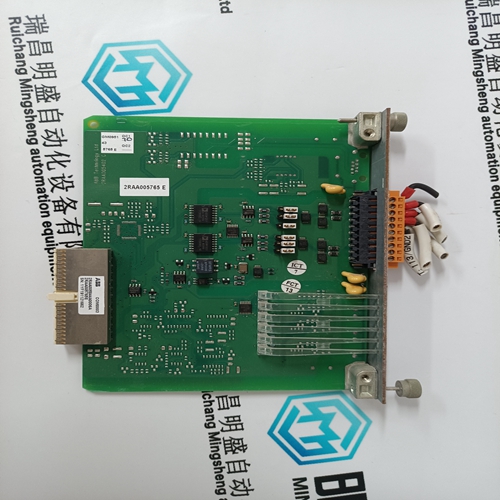

BENTLY 1900/65A-01-02-01-00-00 Monitor module

- Product ID: 1900/65A-01-02-01-00-00

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY1900/65A-01-02-01-00-00Monitor module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

BENTLY 1900/65A-01-02-01-00-00 Monitor module

The figures given in brackets refer to the block circuit diagrams in Chapter 5.2.2 “Block circuit diagrams“ from page 20 on. The operating principle of the complete system is explained in data sheet RE 30028. The digital control electronics VT-VPCD consists of a swivel angle controller, a pressure controller and a valve controller as well as of a power limiter. The position of the pump‘s swashplate is sensed by an inductive swivel angle transducer, the actual pressure value is sensed by a pressure transducer. Both actual values are fed to the control electronics and linked to each other by software. The actual power value is formed by the product of actual pressure value and actual swivel angle value. The controller software ensures with the help of a minimum value comparator that only the controller is active, which is assigned to the relevant working point. The control electronics is designed as double-sided printed-circuit board in Eurocard format 100 x 160 mm. It comprises a switched-mode power supply unit [1], which generates all the internally required voltages.

Product description

The central unit is a micro-controller, which controls the entire sequence and realizes the functions of the controller. Configuration data, command values and parameters are saved in a non-volatile FLASH. Four binary-coded digital inputs are used for calling up parameter sets (command values) from the memory, in which a maximum of 16 sets can be saved. A call-up activates a command value for the swivel angle, pressure and power limitation as well as ramp times for swivel angle and pressure. Further control inputs assume the following functions: “Command valid“: Enable of the parameter set addressed by the current call-up (H-active) “Enable“: Activation of control (H-active) Remark: H-active = High-active Level L-active = Low-active Level L/H edge = Low/High edge The analog command values for swivel angle, pressure and maximum power are provided via differential inputs AI7, AI5 and AI4 [3]. With a positive swivel angle command value, the pump swivels “to the left” (= direction of flow P -> B). The digital call-up command values are added to the analog command values, and the sum of both are fed via the relevant ramp generator to the input of the controller.

Open circuit

When the axial piston pump A4VSO...HS4 is operated in the open circuit, a valve connection block is installed between the axial piston pump A4VSO.. and proportional valve 4WRE6-2X/822. The variant of the valve connection block depends on the pump’s direction of rotation.

The output signal of the controller activates the output stage [6] in dependence on command/actual differences. The position of the valve spool [11], the swivel angle of the variable displacement pump [12a, 12b or 12c] and the system pressure [13] are measured and fed via evaluation electronics [7] to the control loop. 5.2.1 Circuit variants The axial piston pump A4VS...HS4 can be operated within various circuit variants. Adjustments are therefore necessary on the axial piston pump for each variant. The following circuit variants are possible: Hydraulic circuit variants • Open circuit • Closed circuit Pump combinations (master/slave) • Circuit with pressure sensorics - current • Circuit with pressure sensorics - voltage