Home > Product > Robot control system > RAMIX PMC661J mechanical module

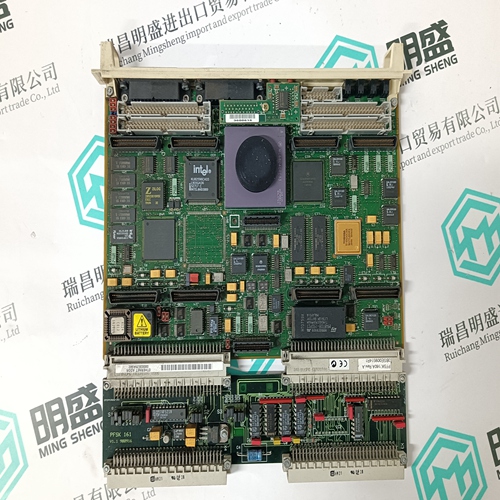

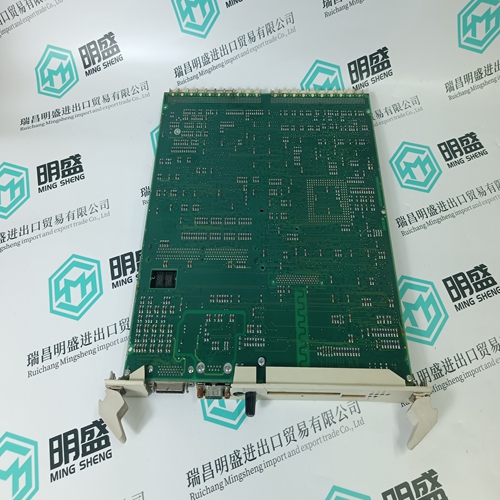

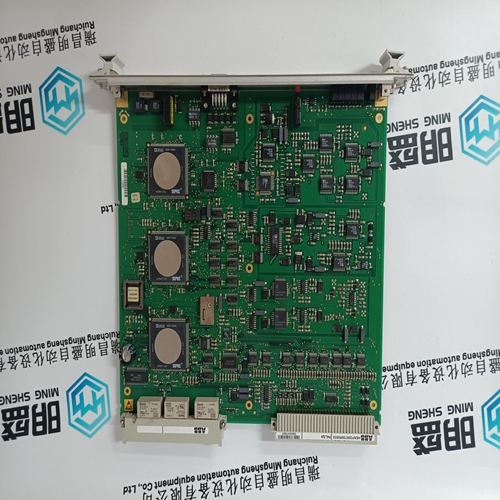

RAMIX PMC661J mechanical module

- Product ID: PMC661J

- Brand: RAMIX

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:RAMIXPMC661Jmechanical module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

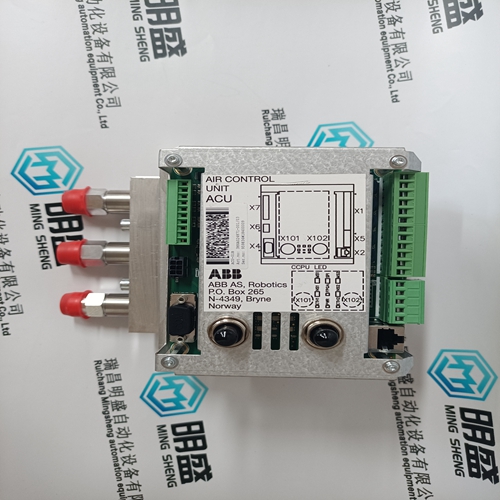

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

RAMIX PMC661J mechanical module

Optionally, a by-pass valve Z4WEH (WB152) (4/2 directional shut-off valve) can be installed additionally between the sandwich plate and the proportional valve. The by-pass circuit does not feature an emergency stop function! The by-pass circuit serves for adjustment and setting purposes in the de-pressurized zero position, but without a defined return during high-pressure operation. When several pumps deliver fluid into a system, they have to be connected in parallel. If pressure control is to be activated for them, it is useful to apply the master/slave principle. To this end, one pump is used as master, and all the other pumps are hooked up as slaves. One pressure transducer can be connected to several control electronics. In the case of pressure sensors with current interface, the resulting load impedance must be taken into account (load impedance per control electronics 100 Ω). The voltage drop across an input is 3.5 V at 20 mA and 1.7 V at 4 mA. The master board realizes closed-loop swivel angle control as well as closed-loop pressure control and power limitation. For this, the swivel angle, pressure and power command values have to be provided accordingly. The swivel angle command value (b2) of all slave boards is to be connected to the output (d32) of the master board

Pump combinations (master/slave)

For master/slave operation, the swivel angle command value (b4) of all slave boards must be connected to the output (b28) of the master board. The pressure controller must then only be adapted on the master board. The slave boards are always operated using the resulting command value of the master board.It is also possible to realize a master/slave system using a bus system (Profibus/ DeviceNet/CANopen). In this case, parameters are not transmitted via analog inputs and outputs, but directly over the bus system. This is illustrated in the following Figure.

The freely configurable test sockets X1/X2 provided on the front panel serve to indicate process signals. Their configuration is described in the online help. The following states are signaled by LEDs: • LED “ ” (green): Enable active • LED “OK” (green): OK ready • LEDs “I1“...”I4” (yellow): Binary-coded command value call-ups • LED “I5“ (yellow): Slave mode • LED “I6“ (yellow): Command valid • LED “I7“ (yellow): Not assigned Using keys ENT, ESC, UP, DOWN you can navigate within the menu and access the individual parameters and error messages. The keys are described in detail in Chapter 9.2 “Operating the control electronics VT-VPCD“ from page 24 onwards.

Sign of display value

The signs +/- light up together with the value shown on the display (positive or negative). In conjunction with the 4 keys, the display serves to display and change parameters and is used for diagnostic purposes. The VT-VPCD can be accessed via a menu structure. The parameter values can be displayed and changed. Moreover, error messages are shown on the display. Software is configured via the serial interface. The graphic below shows the pinout of the D-SUB socket on the front panel.

The connection for Profibus communication is made using a 9-pin D-SUB socket on the front panel (optional). The graphic below shows the pinout of the D-SUB socket for Profibus.