Home > Product > DCS control system > TRICONEX DO 3626X Input module

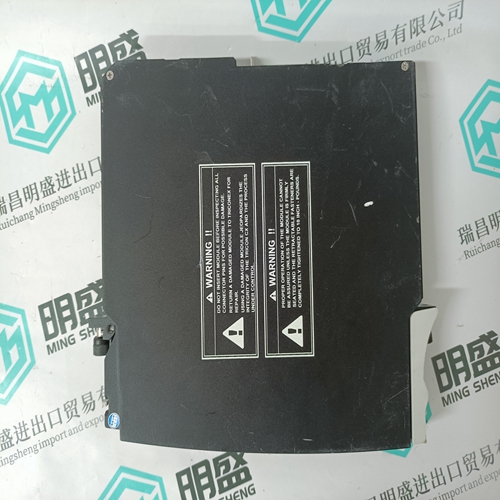

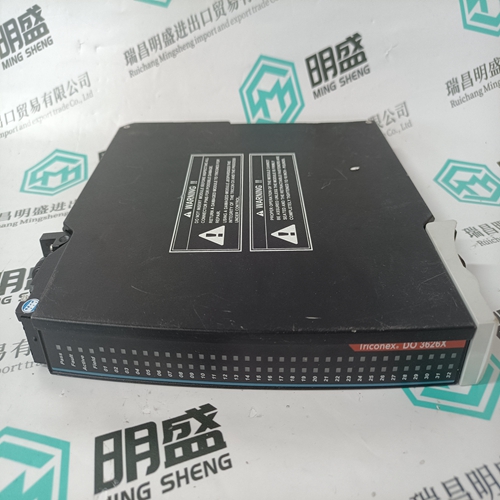

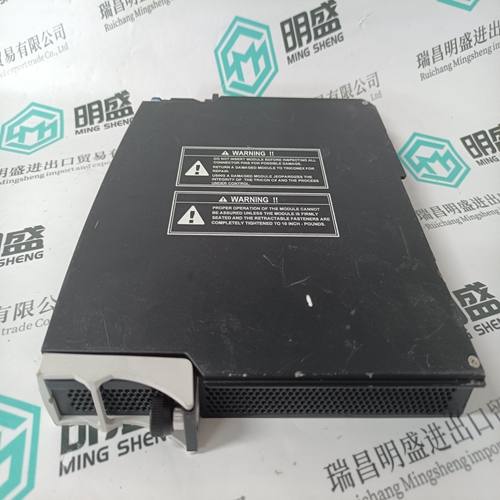

TRICONEX DO 3626X Input module

- Product ID: DO 3626X

- Brand: TRICONEX

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:TRICONEXDO 3626XInput module

- Get the latest price:Click to consult

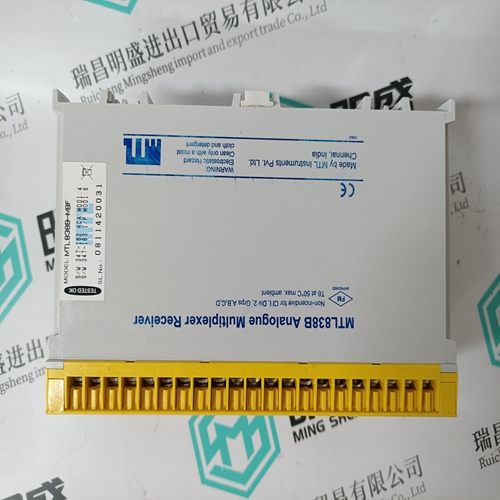

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

TRICONEX DO 3626X Input module

9.3.1 Diagnostic options on control electronics VT-VPCD The diagnostic test jacks on the front panel of the control electronics VT-VPCD (see Chapter 9.1 “Indicator/operating elements and ports of the control electronics“ on page 39) provide two analog outputs with the following ratings: • X1, 10 Volt for test equipment having Ri = 100 kΩ • X2, 10 Volt for test equipment having Ri = 100 kΩ • COM, ground Here, you can select the signal to be measured. The following signals can be output: Pressure command value, swivel angle command value, power command value, actual valve value, actual pressure value and actual swivel angle value. With the help of the BODAC software you can determine the response of the connected actuators (drives, etc.) in the “Error” screen during initial commissioning. When the control electronics detects an error, which was determined in the BODAC software, the error will be signaled on the display of the control electronics VTVPCD. After the control electronics detected an error defined in the BODAC software, please proceed as follows: The letter combination “FAIL” will flash on the display of the control electronics! ▶ Press the “ENT” key to have the error message shown on the display and eliminate the error. The procedure for determining the response in the event of an error is described in the online help.

Diagnostics options using BODAC with WinView

The BODAC software features further, detailed diagnostics options. The “Motion Data” screen and the “Status” screen provide you with an overview of the current state of the control electronics and connected sensors and actuators. For diagnostics, recording and visualization purposes, BODAC operates in conjunction with the visualization software WinView. The required data are acquired in the controls of Bosch Rexroth. The user program hands the data over to WinView, which represents them in a graphic form. The data can be saved in the specific file format .GRA and re-loaded as required. If the necessary WinView version is already installed on your PC, BODAC will integrate it automatically. Otherwise, you are prompted by BODAC to install WinView. You can download WinView free of charge on the Rexroth website

Motion Data screen

The “Motion Data” screen shows the current signal processing of the control electronics. This provides a quick overview of the current state of process data. The Motion Data display works in conjunction with the visualization software WinView.

The “Status” window shows the status of the signals currently present. A subdivision is made by “OK”, WARNING” or “ERROR”. For further information on the Motion Data screen and the Status screen, please refer to the online help

Maintenance In the interest of a long service life and operational reliability include the following activities for the control electronics in your maintenance schedule: • Inspect all terminal connections for correct connection and damage at least once a year. • Inspect all cables for rupture or squashing. • Replace or have defective or damaged control electronics replaced immediately. 10.3 Repair The control electronics VT-VPCD can only be replaced as a complete unit. Unauthorized modifications of the VT-VPCD are not permitted for safety reasons. Repair work may only be carried out by Bosch Rexroth AG. For repairs, return the device to the service address given in Chapter 15.