Home > Product > DCS control system > TRICONEX IMSS 4701X Input module

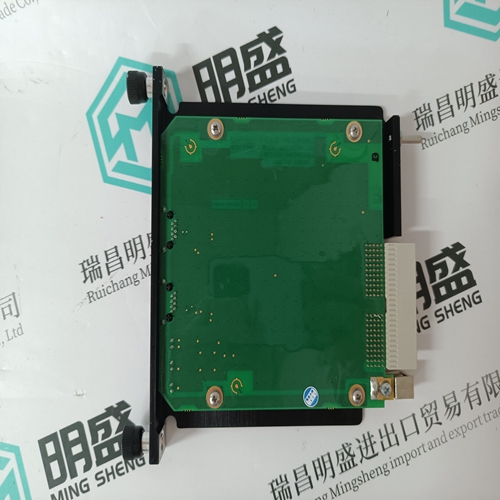

TRICONEX IMSS 4701X Input module

- Product ID: IMSS 4701X

- Brand: TRICONEX

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:TRICONEX IMSS 4701XInput module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

TRICONEX IMSS 4701X Input module

Removal carried out improperly! The control electronics may be destroyed! ▶ Decommission the entire system as described in the general instructions for the system. ▶ Disconnect the control electronics and all connected components from the power supply.Removal Loosen the two mounting screws on the front panel and take the control electronics from the plug-in connection without applying any force. 11.3 Preparing components for storage/further use To prepare the VT-VPCD for storage or further use, proceed as follows: ▶ Whenever possible, use the original packaging for storage or use another, suitable ESD packaging and observe ESD regulations. ▶ Adhere to the permitted storage temperature range, which is specified in RE 30028. ▶ Protect the control electronics against dust and humidity.1 Environmental protection Careless disposal of the VT-VPCD and the packaging material could lead to pollution of the environment. ▶ Therefore, dispose of the VT-VPCD and the packaging material in accordance with the currently applicable regulations in your country and provide for recycling whenever possible.

How to proceed for troubleshooting

Always act systematically and targeted, even under pressure of time. Random and imprudent disassembly and readjustment of settings might result in the inability to ascertain the original cause of fault. • First obtain a general overview of how your product works in conjunction with the entire system. • Try to clarify whether the product worked properly in conjunction with the entire system before the troubles occurred. • Try to determine any changes of the entire system in which the product is integrated: –Were there any changes to the product’s operating conditions or operating range? –Were any changes made or repairs carried out on the complete system (machine/ system, electrics, control) or on the product? If yes, which? –Was the product or machine used as intended? – How did the malfunction manifest itself? – Try to get a clear idea of the error cause. Directly ask the (machine) operator.

Changing the fuse

The control electronics is protected against overvoltage by means of a fuse. The fuse is a single-use fuse with the following data: • F / 4 A / 250 V The fuse can be blown for two reasons: 1. Blowing can be traced back to material fatigue or a product defect. ▶ In this case, replace the fuse with a new one of the above-mentioned type. 2. The fuse is blown due to external effects, i.e. components or parts connected to the control electronics. ▶ In this case, carry out a diagnosis and remedy the fault that caused the fuse to blow. Only then should a new fuse be installed. How to replace the fuse of the control electronics VT-VPCD: 1. Remove the VT-VPCD control electronics from the card holder (reverse of the procedure described in Chapter 7.5 „Installing the VT-VPCD“ on page 30). 2. Gently remove the fuse from the fuse holder without applying any force. See Figure below.