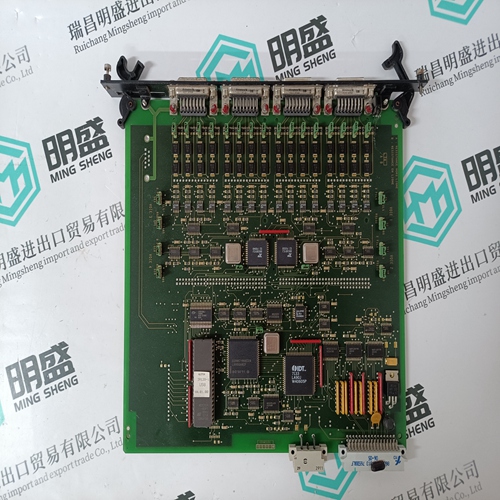

Home > Product > Robot control system > ALSTOM IR139-1 Control card

ALSTOM IR139-1 Control card

- Product ID: IR139-1

- Brand: ALSTOM

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ALSTOM IR139-1 Control card

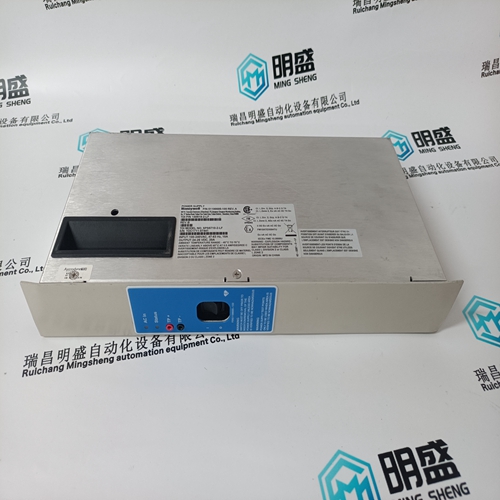

Powering the RDCU The RDCU is powered through connector X34. The unit can be powered from the power supply board of the inverter (or IGBT supply) module, provided that the maximum current of 1 A is not exceeded. The RDCU can also be powered from an external 24 V DC supply. Note also that the current consumption of the RDCU is dependent on the optional modules attached. (For current consumption of optional modules, see their respective user manuals.) Fibre optic connection to inverter/IGBT supply module Connect the PPCS link of the AINT (ACS 800 series modules) board of the inverter (or IGBT supply) module to fibre optic connectors V57 and V68 of the RDCU. Note: The recommended maximum distances for the fibre optic link is 10 m (for plastic [POF] cable). In case longer distances are required, contact an ABB representative.

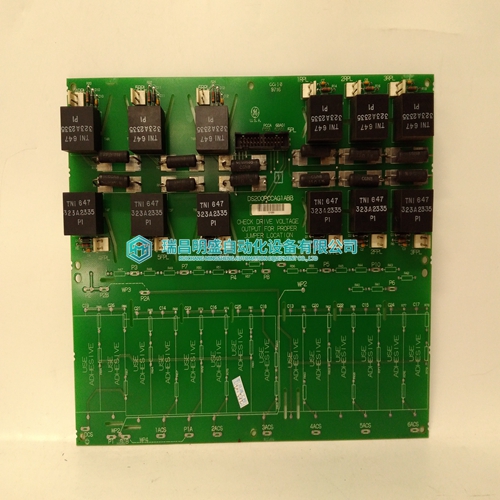

Machines and plant equipment

for reasons of competitiveness are becoming even more complex, the amount of information required from sensors and actuating devices is constantly expanding, causing heavier implementation and higher wiring costs. The ABB Procontic CS 31 is designed to simplify implementation and wiring. The CS 31 is a decentralized automation system. The system is ideally suited to applications where modularity and cost reduction are key factors. The CS 31 system comprises of the following : – a central unit, enclosed within a compact case which can be screw or DIN rail mounted, – remote input/output plug-in units, wich are easily removeable. The plug-in base can be screw or DIN rail mounted, – a simple twisted pair wire arrangement (RS 485), which is utilized for connection of the central unit to the I/O units

System description

The decentralized architecture of the ABB Procontic CS 31 system offers a superior solution to control system requirements: – The central unit can be mounted within the control panel. – The input/output units can be mounted local to the sensors and actuators. As an example the central unit may be connected to remote units distributed along a process line. A cost reduction in wiring is possible upto 80% with the implementation of the CS 31 system.

– decentralized architecture as opposed to centralized system, – reduction of wiring costs (design, materials and commissioning time), – configurable input/output units, – extensive diagnosis functions, – freely expandable network. Additional units can be connected whilst the installation is operational, – simple transparent programming. All remote I/O channels are handled as though they were centralized, – remote I/O facility is integral feature and not an additional unit, – programmable serial communications (RS 232) connection to modem, printer, operator display etc...