Home > Product > DCS control system > HONEYWELL CC-IP0101 gateway module

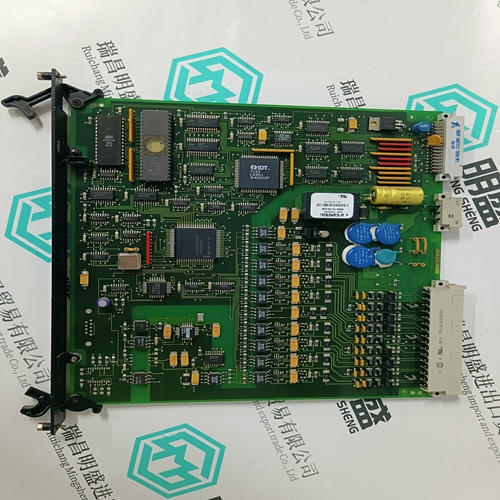

HONEYWELL CC-IP0101 gateway module

- Product ID: CC-IP0101

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELLCC-IP0101gateway module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

HONEYWELL CC-IP0101 gateway module

System constants / Setting of operating modes

– Definitions

At first, the definitions used with the setting of operating

modes are explained :

– Cold start

– Warm start

1°) Cold start

– All of the RAM memories are tested and deleted.

– If there is no user program in the EEPROM, the

default values are set to all of the system constants (identical to the factory settings).

– The operating modes given by the system constants are set.

– The CS31 system bus is initialized again (only

when used as a master on the CS31 system bus).

Performing a cold start

– Command KALT

The change of the central unit operation mode is carried out in three steps : 1. Change system constant KW 0,0 in the central unit. 2. Save user program in the EEPROM. 3. Activate new central unit operating mode with the following steps : – Call menu point "Enable PLC mode" in the ABB programming and test system or – perform a warm start or – perform a cold start.

● Back-up of data areas

Back-up of data areas, i.e. saving of data during power OFF/ON, is onlyfeasible with built-in battery. The following data can be backed, completely or partly : – Binary flags – Words flags – Double word flags – Step chains – Historical values In order to back-up certain data, they have to be excluded from initialization to 0. ● Initialization of data areas During program start, that data areas are initialized to 0 partly or completely, that are defined by system constants. The initialization works as shown in the following table. An external battery is not necessary (see §3.4 Battery).● PLC reaction to class 3 errors – Absolute identifier : KW 0,7 – Symbolic identifier : FK3_REAK – Meaning of the values of the constant : Just output error : 0 Output error and abord PLC program <0, >0 – Range of values : <0, =0, >0 – Default value : 0 i.e. just output error. A change of this system constant becomes effective : – immediately

● Initialization of the CS31

system after power ON, warm start or cold start – Absolute identifier : KW 0,9 – Symbolic identifier : HOCHFAHR – This system constant is only effective if the central unit is configured as a bus master. – Meaning of the values of the constant : The user program is started. The central unit takes no notice of initialization of the CS31 remote units and their adoption into the CS31 bus cycle : =0 The user program is not started until at least n remote units have been initialized and adopted into the CS31 bus cycle : =+n – Range of values : 0…+31 – Default value : 0 i.e. the user program is started immediately.A change of this system constant becomes effective : – with the next warm start or – with the next cold start. ● Size of the transmitting area of the slave central unit – Absolute identifier : KW 00,10 – Symbolic identifier : SLV_SEND – Meaning of the values of the constant : The slave central unit can be used at the CS31 system bus either in the binary area or in the word area. The binary values are transferred byte by byte. It is possible to set the number of bytes (or words) which are to be sent from the slave central unit to the master central unit.