Home > Product > DCS control system > HONEYWELL CC-TDOB11 base module

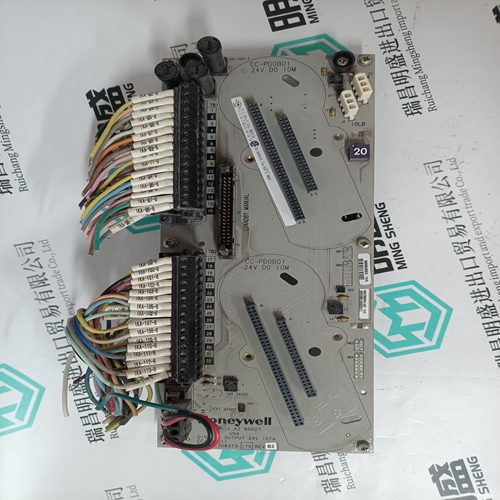

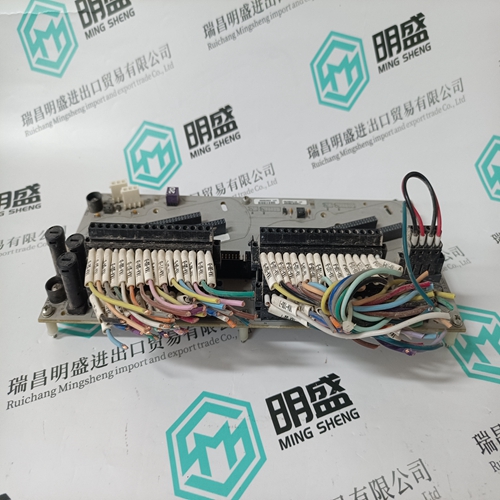

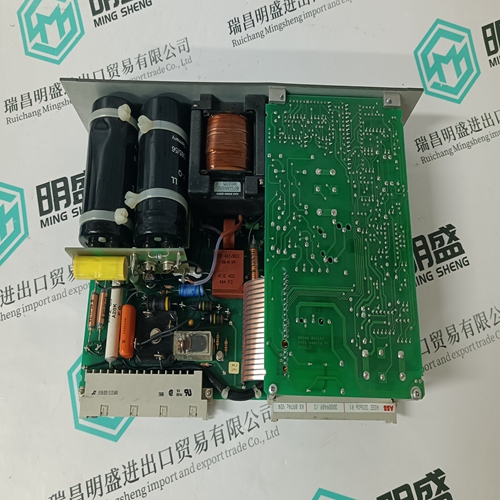

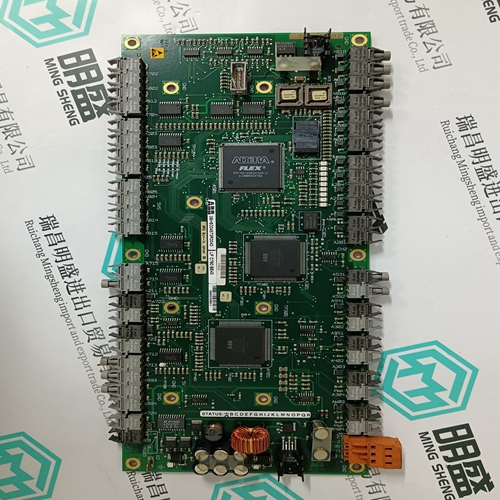

HONEYWELL CC-TDOB11 base module

- Product ID: CC-TDOB11

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELL CC-TDOB11base module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

HONEYWELL CC-TDOB11 base module

The mode MODBUS protocol in the 07 KR 31 and 07 KT 31 depends on the value of the system constant KW00,06 and the connection between the pin 6 and pin 7 on the cable. The mode MODBUS protocol, when it is selected, is always available even if the central unit is in STOP mode. The programming mode is again available when there is no connection between pin 6 and pin 7 ; the program can be tested or modified by the programming software 907 PC 331. ● Master and slave configuration The system constant KW 00,06 selects the status of the central unit on the MODBUS network. The value has to be greater than 100. The slave number is the value of KW 00,06 minus 100. The MODBUS slave numbers are between 01 and 255 so the value of KW 00,06 for a MODBUS slave configuration is from 101 up to 355. The number 00 is for the diffusion of messages (all slaves on the MODBUS network read the message). The value of KW 00,06 for a MODBUS master configuration is 100. ● Communication parameters The factory setting is : – 9600 bauds – parity : none – data bits : 8 – stop bits : 1

Cross reference list

These parameters can be changed with the function block SINIT in the user program. Refer to the documentation of the function block

●List of accessible parameters by the master MODBUS All following parameters of 07 KR 31 / 07 KT 31 can be read or written by the master MODBUS : Bits : E 00,00 upto E 63,15 A 00,00 upto A 63,15 M 000,00 upto M 21,15 and M 230,00 upto M 239,15 and M 255,00 upto M 255,15 S 000,00 upto S 15,15 – in reading n bits (Function codes 01 or 02) – in quick read of 8 bits (Function code 07) – in writing n bits (Function codes 05 or 0F) Words : EW 00,00 upto EW 07,15 AW 00,00 upto AW 07,15 MW 00,00 upto MW 05,15 and MW 230,00 upto MW 239,15 and MW 254,00 upto MW 255,15 KW 00,00 upto KW 07,15 – in reading n words (Function codes 03 or 04) – in writing n words (Function codes 06 or 10)

Reaction time with MODBUS

The traitment time depends on : – the baud rate – the number of bytes of the frame – the cycle time of the central unit – the central unit load The central unit has a buffer of 256 bytes.The traitement by the central unit of the frame starts after the time of 3/2 character after the last received character. ● For a Modbus slave 07 KR 31 / 07 KT 31 The transmission time (sending+receiving) is : (Nb bytes*11/baud)*1000 ms. The basic time in the central unit is : reading n bits : 0.827 ms + nb bits*0.246 ms reading n words : 0.731 ms + nb words*0.182 ms write 1 bit : 1.062 ms write 1 word : 1.025 ms write n bits : 1.113 ms + nb bits*0.039 ms write n words : 1.099 ms + nb words*0.182 ms quick reading of 8 bits : 0.265 ms The traitment time in the central unit is: Cycle time + (INT(basictime / ((1-load)*cycle time)))*cycle time The total response time is : sending time + traitment time in the central unit + receiving time