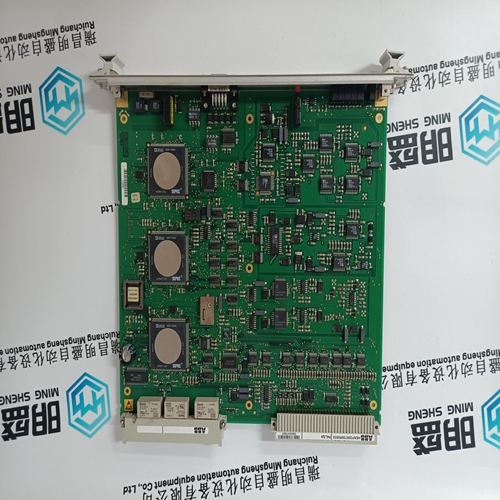

Home > Product > DCS control system > ABB PTU810 Module Mounting Base

ABB PTU810 Module Mounting Base

- Product ID: PTU810

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBPTU810Module Mounting Base

- Get the latest price:Click to consult

ABB PTU810 Module Mounting Base

• Oversized feed material decreases capacity and can cause unnecessary loading on the crusher components. • Small feed size increases wear at the bottom of the cavity and may cause poor utilization of wear parts.

• An uneven wear profile will decrease capacity, increase wear, and increase crushing forces.

Check the feed arrangement

• In order to reach optimum capacity and maximize on the life of the wear parts, the crusher cavity should be full.

• The feed must be distributed evenly across the crushing chamber.

Fines (material smaller then CSS) should be removed from the feed material. This is done by the grizzly bar section of the feeder. Fines in the jaw crusher increase the percentage of contact area against the jaw dies. This increases scratching and grinding and reduces life time.

![]()

![]()

![]()

![]()

Superior products

We mainly make spare parts for DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: professional off production accessories,

Fast delivery, accurate delivery time,

Main brands include ABB, GE/FANC, FOXBORO, TRICONEX, BENTLY NEVADA, A-B, EMERSON, OVATION, MOTOROLA, XYVOM, HONEYWELL, REXROTH, KUKA, NI, DEIF, Reliance Electric, Yokogawa, WOODWARD, SCHNEIDER, MOOG, PROSOFT and other brands

About us

We are professional company and we are expert in this business, we have highly experienced production team, or sales team, or purchase team, we have most advanced production line. We are reputable in the market

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/