Home > Product > Robot control system > ANYBUS ABDT-PDP 3183203131 mechanical module

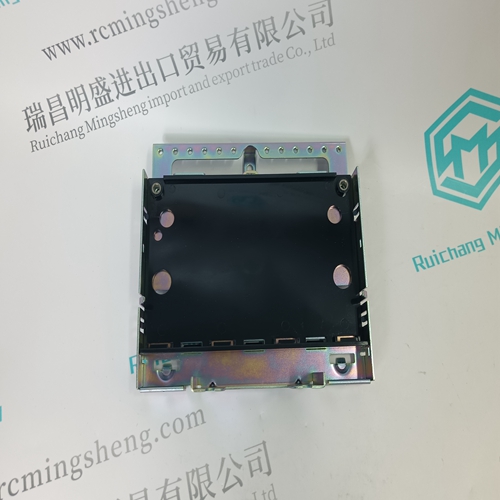

ANYBUS ABDT-PDP 3183203131 mechanical module

- Product ID: ABDT-PDP 3183203131

- Brand: ANYBUS

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ANYBUSABDT-PDP 3183203131mechanical module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ANYBUS ABDT-PDP 3183203131 mechanical module

The user program is continued after a preceding stop (”W”). When continuing, the flags and internal statuses have the same value as with program stop. Timers which have started continue to run independently of the program status in the operating system. They are aborted only by a cold–start or power OFF/ON.The status (program at breakpoint, program aborted, program stopped, program running) of the user program is displayed.The entire PLC status is displayed as follows: Program identification Cycle time Program status Active test functions TRACE registers Error messages Capacity utilization

In TRACE mode, the PLC notes the address of the block last executed or the address of the instruction last executed. After a system crash, the operator is thus provided with information as to how far the user program has been executed. The contents of the TRACE memory are retained in the event of a RESET.

The user program is stopped.

The values of the outputs and of the flags are retained. Timers which have been started continue to run independently of the program status in the operating system. They are aborted only by a cold–start or power OFF/ON.

Name of the variable or indirect constant value: New value which is to be assigned to the variable ;: There must be a semicolon between the name and the value of the variable. If several variables are to be overwritten, these must also be separated by a semicolon. Note: If the variable is a step variable, it can only be set and not reset. When step variables are set, all other steps of the chain are automatically reset. If an indirect constant is modified with this command, this modification is performed only in the operand memory and not in the program memory, i.e. this value is overwritten again by the value from the program memory with the next program start.

The individual variables must be separated by semicolons. L number: Number of consecutively numbered variables as of the variable var which are to be displayed. Example: M 0,0 L 3 The following are displayed: M 0,0 M 0,1 M 0,2

Operating and test functions

The values of the variables (max. 22) are each

updated when character Z