Home > Product > DCS control system > HONEYWELL CC-PAON01 Switch module

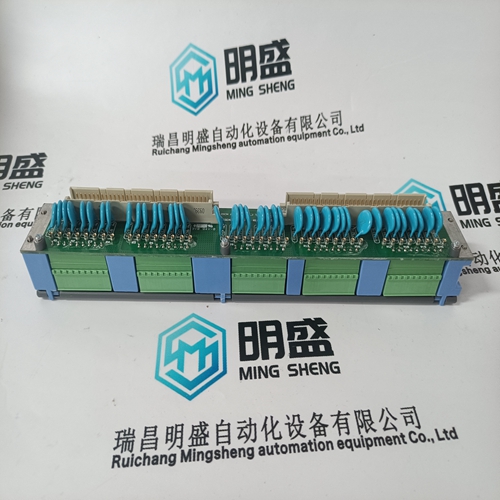

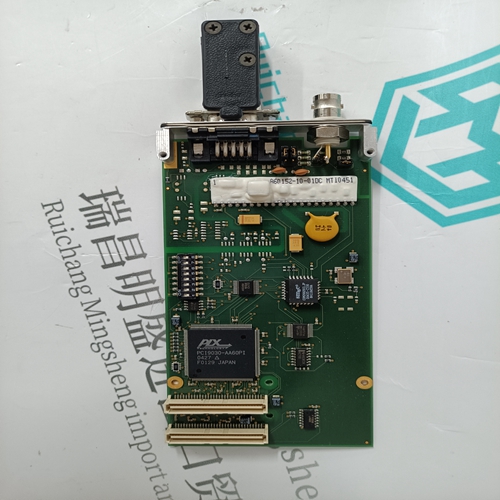

HONEYWELL CC-PAON01 Switch module

- Product ID: CC-PAON01

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELLCC-PAON01Switch module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

HONEYWELL CC-PAON01 Switch module

When a system is built up, the branching units addresses must be set according to a certain hierarchy. Principal is that the closest branching unit to PC must always have biggest address number. (The addresses are set by dip switch S1 located on the branching units type NDBU-85/95; see chapter 1, section “Layout of branching units type NDBU-95”).

In today’s world of brilliant machines, operators require high-performance automation solutions that seamlessly connect their machines, data, and people while ensuring the safety and integrity of their process and equipment. The Mark VIeS Functional Safety System is born from a decades-long heritage of turbine protection and control. The Mark VIeS system is a cost-effective, complete, flexible, and reliable functional safety system with enhanced cyber security for critical processes such as plant emergency shutdown, burner management, critical process control, and fire and gas detection applications.

A proven and safe solution

GE brings decades of domain expertise to the Mark VIeS Functional Safety System. The Mark series of controllers has earned a reputation for superior running reliability and superior tripping reliability when required in thousands of TMR systems installed in power generation and infrastructure applications globally. These proven philosophies are atthe heart of the Mark VIeS Functional Safety System.

Flexibility and reliability

Redundancy is a critical feature in safety control system design, enabling continuous process operation during system maintenance or repair. The Ethernet backbone of the Mark VIeS Functional Safety System allows each segment of the system to be configured with different levels of redundancy as follows: • Can be: Simplex, Dual, or TMR • I/Onetwork (IONet) communications can be: Simplex, Dual, or TMR • I/O modules can be: Simplex or TMR This flexibility enables customers to design their system to meet the exact needs of their SIL application requirements, and ultimately reducing system costs. Customers can customize the level of redundancy to meet safety and running reliability needs.

Enhanced productivity and efficiency

Sophisticated application automation tools and seamless data integration between the control system and Humanmachine Interface (HMI) enable process efficiencies during project execution to reduce delivered cost and improve quality. Enhanced software reusability features allow users to create and maintain logic standards that can then be efficiently deployed over and over again. This reduces project costs, increases the integrity of software, and reduces the risk of human error. All of these are critical considerations when deploying safetyrelated systems. Seamless integration with basic process control system GE understands the importance of seamless integration between your safety and existing control solutions. The Mark VIeS control system offers flexibility, scalability, and standards- based operational interfaces to securely integrate with your existing process control systems. This integration allows world-class safety functionality to securely connect to existing processes, and create a seamless safety program.