Home > Product > DCS control system > HONEYWELL CC-TCNT01 base module

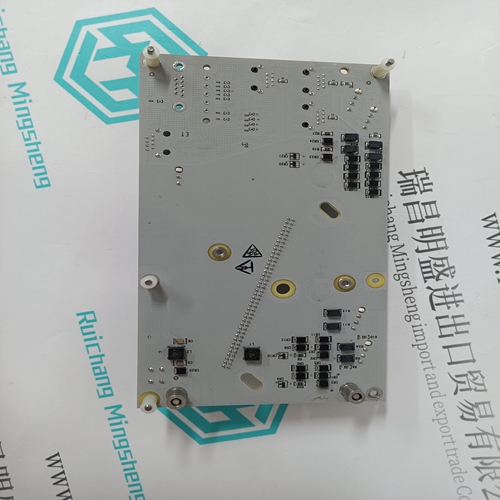

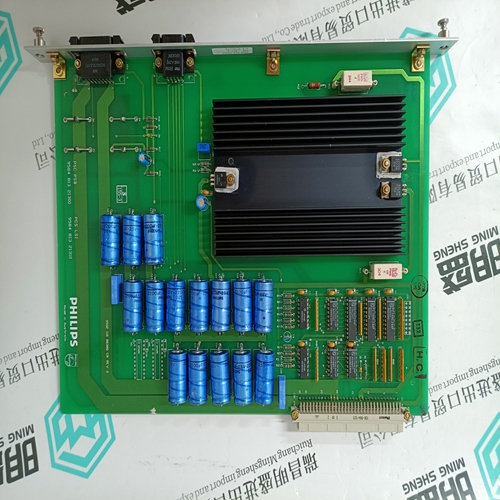

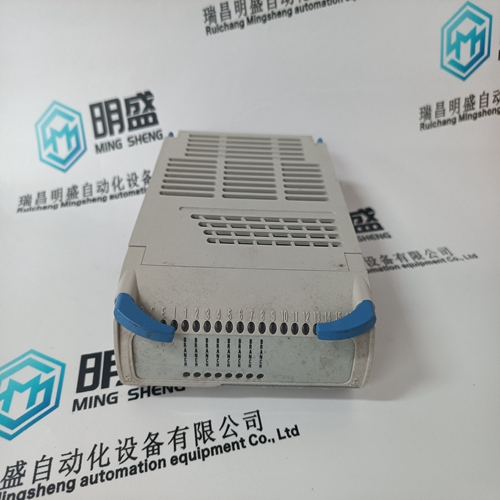

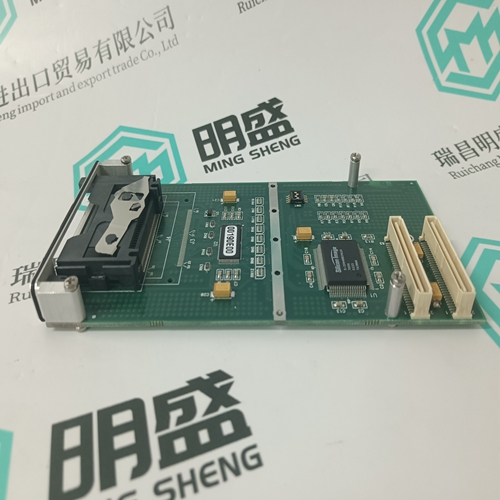

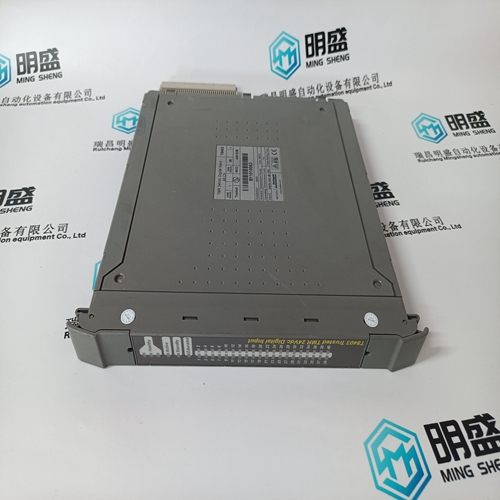

HONEYWELL CC-TCNT01 base module

- Product ID: CC-TCNT01

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELLCC-TCNT01base module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

HONEYWELL CC-TCNT01 base module

Humidity The ambient humidity range is 5 to 95% non-condensing. This exceeds EN50178. Elevation Equipment elevation is related to the equivalent ambient air pressure: • Normal operation: 0 to 1000 m (0 to 3280.8 ft, 101.3 to 89.8 kPa) • Extended operation: 1000 to 3050 m (3280.8 to 10006.5 ft, 89.8 to 69.7 kPa) • Shipping: 4600 m (15091.8 ft, 57.2 kPa) maximum

he ToolboxST * application features include: • System component (controllers, I/O packs, WorkstationST * ) layout and configuration • Configure, edit, and view real-time controller application code • Ethernet Global Data (EGD) editor • Component diagnostics • Password protection

The Trender application is used to capture both real-time and historical data for display in graphical form. Several forms of data collection are supported for a wide range of resolution. Trigger configured data collections are also supported.

Temperature Considerations

Mark VIeS electronics can be I/Opackaged in a variety of different configurations and designed for different environmental conditions. Proper thermal considerations for active electronics with heat sensitive components must be considered for electronics I/Opackaging. For internal enclosed design considerations, all components have an ambient temperature rating of -30 to 65°C (-22 to 149°F). The allowable temperature change without condensation is ±15°C (59°F) per hour. It is recommended that the environment be maintained at levels less than the maximum rating of the equipment to maximize product life expectancy. I/Opackaging the equipment and selecting an appropriate enclosure to maintain the desired temperature is a function of the following: • Internal heat dissipation from the assemblies • Outside ambient temperature • Cooling system (if used)

The Alarm Viewer application displays

and manages live and historical alarm and event information. Alarm and event information is displayed in tabular form with advanced filtering and sorting capabilities. Common functions provided around the process alarms/events include: • Acknowledging Alarms • Locking Alarms • Silencing Alarms • Sequence of Events (SOE) • Component Diagnostic Alarms

The WorkstationST OPC ®-DA server provides a common interface between the safety system and other control systems. The OPC-DA server conforms to the 2.0 data access standards. The OPC standard defines two software roles, OPC clients and OPC servers. In general, clients are consumers of automation information and servers are producers of the same information. The Control System Health (CSH) system collects diagnostic data on various hardware/software components and makes it available in a combination of three ways: • Control System Health Viewer application where the user can navigate to a component or critical application and view health status • Alarm Viewer application includes a complete set of control system component diagnostic alarms in addition to the process alarms • Alarm Viewer application includes a complete set of control system component diagnostic alarms