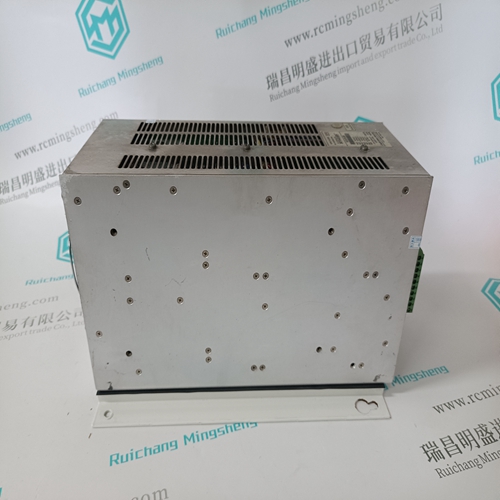

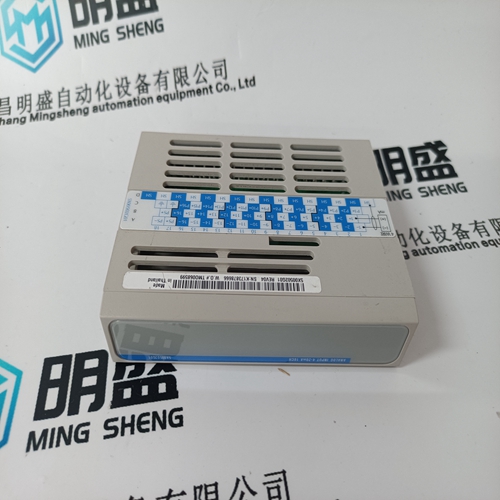

Home > Product > Robot control system > ABSOLUTE MOX12-P3509 B 80026-173-23 module

ABSOLUTE MOX12-P3509 B 80026-173-23 module

- Product ID: MOX12-P3509 B 80026-173-23

- Brand: ABSOLUTE

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABSOLUTEMOX12-P3509 B 80026-173-23module

- Get the latest price:Click to consult

The main products

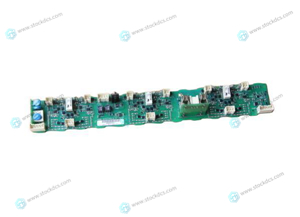

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ABSOLUTE MOX12-P3509 B 80026-173-23 module

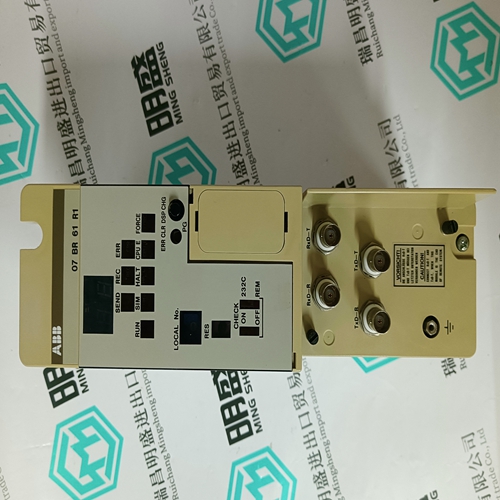

This is the work area of the controller after it is powered up. The SMC Flex controller uses an Auto Store feature when you program parameters. When you modify parameters in the program mode, the new values are stored immediately in RAM and then in EEPROM, once the enter key has been pressed. If control power is lost prior to the enter key being pressed, these values are lost. When the device first powers up, the values from the EEPROM area of memory are copied into RAM.

The SMC Flex controller comes with factory default parameter values. These settings are stored in non-volatile ROM and are displayed the first time you enter the Program mode. You can restore defaults at any time by accessing the memory storage menu The SMC Flex controller provides a non-volatile area for storing user-modified parameter values in the EEPROM.

Parameter Modification

All parameters are modified using the same method. Table 19 lists the basic steps for modifying parameters. Parameter values modified while the motor is operating are not valid until the next time that operation occurs. If the password is set, you cannot adjust parameters without logging in. Use the Sel key to highlight a single digit.The SMC Flex controller lets you select between two Start profiles. The parameters that are listed in Table 22 are available in the Set Up menu. Ramp #1 parameters are in the "Basic Setup" menu. Ramp #2 parameters are in the "Dual Ramp" menu. Option Input 2 must be set to "Dual Ramp" to enable the second ramp parameters.The Ramp #2 parameters will be used if Option Input 2 is active at the time of the start. To obtain Dual Ramp control, Ramp #1 is located in the Setup menu Basic section and Ramp #2 is located in the Option Input 2 (Dual Ramp).

Full Voltage Start

You can program the SMC Flex controller to provide a full-voltage start (output voltage to the motor reaches full voltage within 1/4 second) with the parameters that are listed in Table 23.The SMC Flex controller lets you control the motor speed during starting and stopping maneuvers. A tachometer input is required. See page 10.The Basic Setup programming group provides a limited parameter set, allowing quick startup with minimal adjustment. If you plan to implement some of the advanced features (such as Dual Ramp or Preset Slow Speed), select the Setup programming group. It provides the complete Basic Setup parameter set and the advanced set.While the Basic Setup group lets you get started with a minimum number of parameters to modify, the Motor Protection group allows full access to the SMC Flex controller parameter set. Table 27 lists the additional setup parameters that are provided in this group.