Home > Product > DCS control system > KSD211B 3BHE022455R1101 coupler

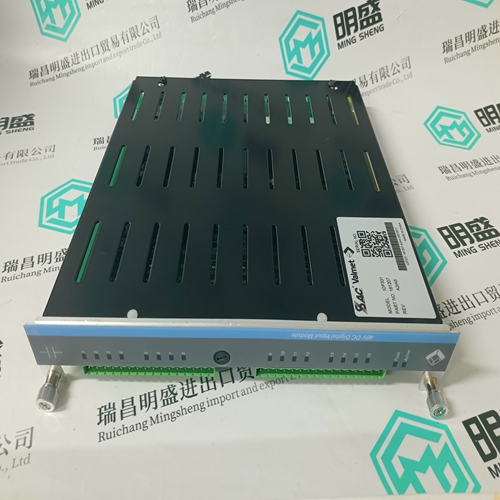

KSD211B 3BHE022455R1101 coupler

- Product ID: KSD211B 3BHE022455R1101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:KSD211B 3BHE022455R1101coupler

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

KSD211B 3BHE022455R1101 coupler

The default configuration for I/O is 4 bytes in and 4 bytes out (TX = 4 bytes, RX = 4 bytes). The total size may very when used with a communication card. The default configuration is arranged according to the following table.The SMC Flex controller supports 16-bit DataLink™, which means that you can configure the device to return additional information. The I/O message size depends on how many DataLinks are enabled. The following table summarizes the I/O data sizes.The total size produced or consumed may vary, depending on the communication card being used. For more information, refer to the User Manual for the communication card.

The increased transmisison sizes for Ethernet (and ControlNet) option modules is due to a required 2-word /4-byte overhead. To configure DataLink, see page 103.

Reference/Feedback

The SMC Flex controller does not offer the analog Reference feature. The analog Feedback feature is supported and will provide Parameter 1, Current in Phase A, automatically as the feedback word. Parameter Information A complete listing of the SMC Flex parameters is in the spreadsheet that is attached to this pdf. See page 7. Scale Factors for PLC Communication The parameter values stored and produced by the SMC Flex controller through communication are unscaled numbers. When reading or writing values from a PLC image table, it is important to apply the proper scaling factor, which is based on the number of decimal places. Read Example Power Factor (Parameter 11)— The stored value is 85. Because this value has two decimal places, the value should be divided by 100. The correctly read value is 0.85.

Motor FLC (Parameter 46)— The value that is to be written to the SMC Flex controller is 75 A. Because this value has one decimal place, the value should be multiplied by 10. The correctly written value is 750.

Display Text Unit Equivalents

Some parameters have text descriptions when you view them from a HIM or through a communication software program such as RSNetworx™. When receiving or sending information from a PLC, each text description has a numerical equivalent. Table 41 shows an example of Overload Class (Parameter 44) and the appropriate relationship between the text descriptor and the equivalent value. This relationship is identical for other similar parameters.

DataLink™ is supported in the SMC Flex controller. DataLink is a mechanism that most drives use to transfer data to and from the controller without using an explicit message. The SMC Flex controller supports a 16-bit DataLink, allowing you to configure the device to return up to four additional pieces of information without the need for an explicit message.