Home > Product > Servo control system > WOODWARD 5466-409 Hydraulic governor

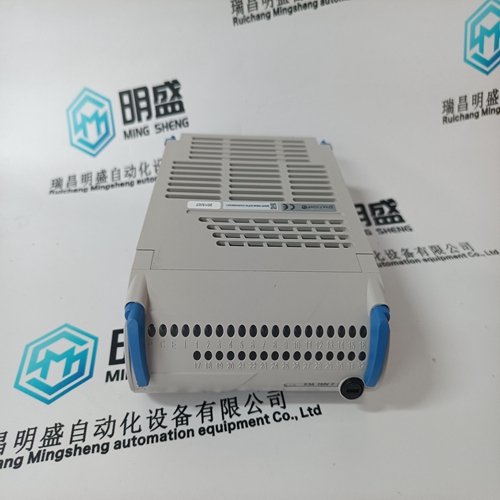

WOODWARD 5466-409 Hydraulic governor

- Product ID: 5466-409

- Brand: WOODWARD

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:WOODWARD5466-409Hydraulic governor

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

WOODWARD 5466-409 Hydraulic governor

The SMC Flex controller stores in memory the five most recent faults. Display the fault buffer by selecting the View Faults Queue and scrolling through the fault buffer parameters. The information is stored as fault codes and fault descriptions. The five most recent faults are also stored as the values of Fault 1 (Parameter 124) through Fault 5 (Parameter 128). Fault 1 is the current fault and Fault 5 is the oldest fault in memory. Fault Codes Table 42 provides a complete cross-reference of the available fault codes and corresponding fault descriptions.

You can program auxiliary contacts for Fault or Alarm, N.O., or N.C. indication. Parameter setup is in the Parameter/Motor Protection group when you modify parameters in Program Mode. Fault Definitions Table 43 shows the fault definitions for the SMC Flex controller. The unit trips and stops after any of these faults occurs.

Troubleshooting

For safety of maintenance personnel and others who might be exposed to electrical hazards associated with maintenance activities, follow the local safety related work practices (for example, NFPA 70E, Part II in the United States). Maintenance personnel must be trained in the safety practices, procedures, and requirements that pertain to their respective job assignments.

SHOCK HAZARD: Hazardous voltage is present in the motor circuit even when the SMC Flex™ controller is off. To avoid shock hazard, disconnect main power before working on the controller, motor, and control devices (for example, Start-Stop push buttons). Procedures that require parts of the equipment to be energized during troubleshooting, testing, etc., must be performed by properly qualified personnel using appropriate local safety work practices and precautionary measures. ATTENTION: Disconnect the controller from the motor before measuring insulation resistance (IR) of the motor windings. Voltages used for insulation resistance testing can cause SCR failure. Do not make any measurements on the controller with an IR tester (megger).

Power Module Check

The time it takes for the motor to come up to speed may differ from the time programmed. This depends upon the motor and load characteristics. Depending upon the application, the braking options (SMB and Slow Speed) may cause some vibration or noise during the stopping cycle. To minimize vibration or noise, lower the braking current adjustment. If this is a concern in your application, please consult your local Rockwell Automation sales office or Allen-Bradley distributor before you implement the braking options.

Shorted SCR Test Using an ohmmeter, measure the resistance between the line and load terminals of each phase on the controller. (L1-T1, L2-T2, & L3-T3) The resistance should be greater than 5,000 Ω.