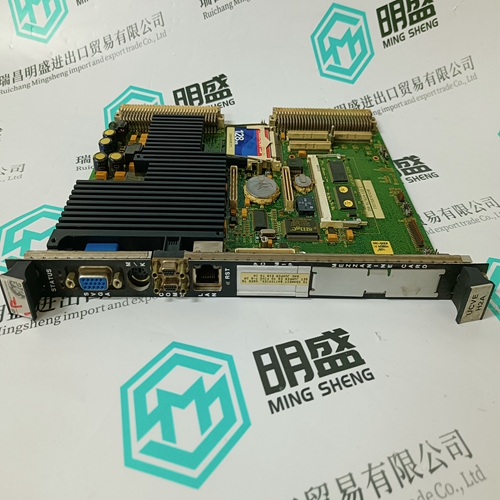

Home > Product > Robot control system > EATON MP3010 Operation panel

EATON MP3010 Operation panel

- Product ID: MP3010

- Brand: EATON

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:EATONMP3010Operation panel

- Get the latest price:Click to consult

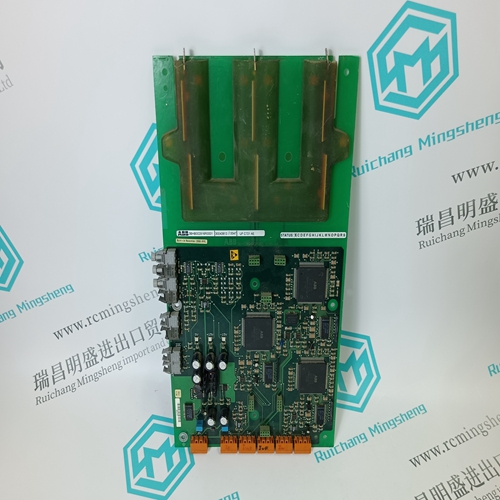

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

EATON MP3010 Operation panel

In many applications, it is necessary to read or write floating-point data to the device. The sample program only provides an INT array for the ReadData and Write Data array (16-bit signed integer value). In order to read/write floating-point data to and from the device, you must add additional ladder logic to handle the conversion of the data to a REAL data type within the FLEX processor. This is very easy to accomplish. The following topics show how to read or write data to a device. These topics also show when to use the Float Flag and Float Start parameters within the module configuration. For all applications, floating-point data can be read from a device without any changes to the Float Flag and Float Start parameters. You only need to configure these parameters to issue a Write command to a device that uses a single Modbus address, such as 47001, to represent a single floatingpoint value. The MVI94-MCM module can be used with many different processors. The following describes using the module with a ControlLogix processor.

Floating-Point Data Handling (Modbus Master)

In many applications, it is necessary to read or write floating-point data to the Slave device. The sample program only provides an INT array for the ReadData and Write Data array (16-bit signed integer value). In order to read/write floatingpoint data to and from the Slave device, you must add additional ladder to handle the conversion of the data to a REAL data type within the ControlLogix processor. This is very easy to accomplish. The following topics show how to read or write data to a Slave device. These topics also show when to use the Float Flag and Float Start parameters within the module configuration. For all applications, floating-point data can be read from a device without any changes to the Float Flag and Float Start parameters. You only need to configure these parameters to issue a Write command to a device that uses a single Modbus address, such as 47001, to represent a single floating-point value

Flex I/O Platform

Along with the Function Code 3, DevAddress 256 will read Modbus address 40257 of the Slave device. The above command will read 40257 and 40258 of the Modbus Slave #1 and place that data in MCM.DATA.READDATA[0] and [1]. Within the controller tags section of the ControlLogix processor, it is necessary to configure a tag with the data type of "REAL" as shown in the following illustration. [+] Energy_Consumption REAL[1] Float Copy data from the MCM.DATA.READDATA[0] and [1] into the tag ENERGY_CONSUMPTION that has a data type of REAL. Use a COP statement within the ladder logic. Here is an example.

Because the tag MCM.DATA.READDATA[0] should only be used within the above command, an unconditional COP statement can be used. Notice the length of the COP statement is a value of 1. Within a Rockwell Automation processor, a COP statement will copy the required amount of "Source" values to fill the "Dest" tag for the Length specified. Therefore, the above statement will copy ReadData[0] and [1] to fill the 32 bits required for the tag "Energy_Consumption". Note: Do not use a MOV statement. A MOV will convert the data from the Source register to the destination register data type. This would create a data casting statement and will result in the loss or corruption of the original data.