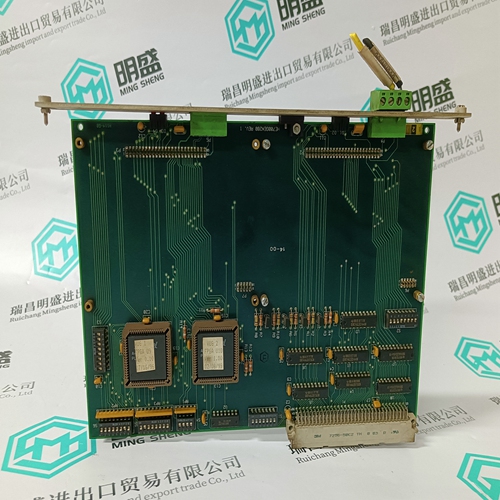

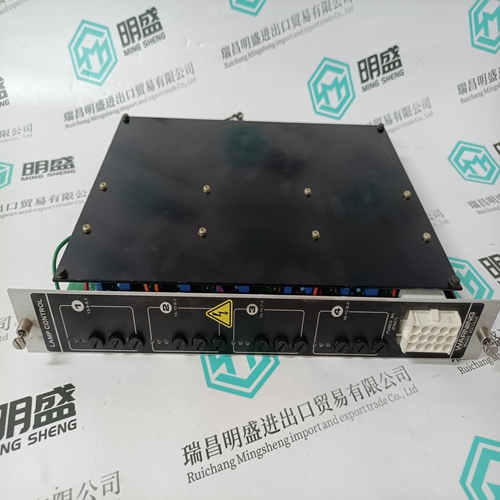

Home > Product > DCS control system > TRICONEX MP3101 Processing module

TRICONEX MP3101 Processing module

- Product ID: MP3101

- Brand: TRICONEX

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:TRICONEX MP3101 Processing module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

TRICONEX MP3101 Processing module

The module can be configured to place slave devices that are not responding to commands at a lower priority. If the module recognizes a slave device has failed to respond to a message after the user defined retry count, it will mark the slave as "in communication failure" and set the error delay counter to the specified value. Each time the module encounters this slave in the command list, the counter will be decremented. When the value reaches zero, the slave will be placed in an active status. This facility can improve communication throughput on the Modbus network. Commands can be activated in the module under processor control. This feature permits the processor to issue a command in the command list under program control. When a command is activated, it will be placed in the command queue for immediate execution. Normal command polling will begin after the command queue is completely processed. Additionally, the processor can send a command directly to any slave attached to the Modbus master port. This feature can be used for commands that are not issued on a regular basis and are not in the command list. Commands submitted as events are placed in the command queue for immediate execution. They will preempt normal operation of the poll list. When the command queue is completely empty, normal command polling will resume.

About the MODBUS Protocol

MODBUS is a widely-used protocol originally developed by Modicon in 1978. Since that time, the protocol has been adopted as a standard throughout the automation industry. The original MODBUS specification uses a serial connection to communicate commands and data between Master and Slave devices on a network. Later enhancements to the protocol allow communication over other types of networks. MODBUS is a Master/Slave protocol. The Master establishes a connection to the remote Slave. When the connection is established, the Master sends the MODBUS commands to the Slave. The MVI94-MCM module can work as a Master and as a Slave. The MVI94-MCM module also works as an input/output module between itself and the Rockwell Automation backplane and processor. The module uses an internal database to pass data and commands between the processor and Master and Slave devices on MODBUS networks.

Data in the virtual Modbus

database is accessible through a configured Modbus slave port. Remote Modbus master devices can monitor and control data in this database through this port. The module provides a Configuration/Debug port for use with an external computer executing a terminal emulation program. The terminal emulation program provided with the module permits uploading and downloading of the configuration information required by the module. Additionally, the Configuration/Debug port provides a view into the virtual Modbus database, communication statistics and the configuration.