Home > Product > DCS control system > DSAI146 3BSE007949R1 Input module card

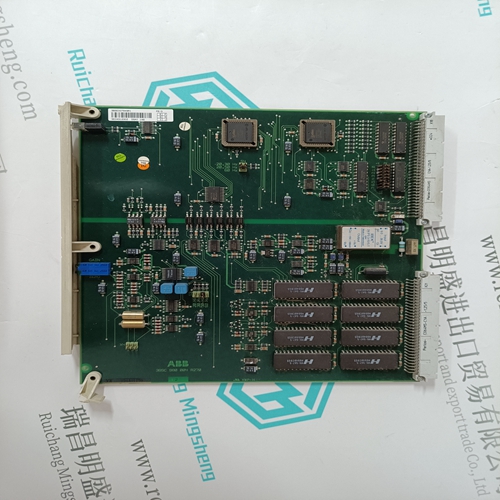

DSAI146 3BSE007949R1 Input module card

- Product ID: DSAI146 3BSE007949R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:DSAI146 3BSE007949R1Input module card

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

DSAI146 3BSE007949R1 Input module card

When the module receives one of these blocks, it examines word 0 of the output image. This word defines the number of commands contained in the block. The command count is determined by subtracting 2000 from the word value. This permits the controller to set from one to six commands into the command queue. The indexes submitted in the block should be valid for the command list. After the module determines the number of commands to consider, it inserts each command in the command queue. The response message sent from the module to the processor is as follows:The ladder logic can examine word 2 of the input image to determine the number of commands placed in the command queue. Any errors associated with the command can be viewed in the command list error table.

Transferring the Command Error List to the Processor

You can transfer the command error list to the processor from the module database. To place the table in the database, set the Command Error Pointer parameter to the database location desired. To transfer this table to the processor, make sure that the Command Error table is in the database area covered by the Read Data. Pass-Through Blocks (9956 to 9958, 9960) When the port is configured as a slave with pass-through, Modbus write commands 5, 6, and 22 that are addressed to the slave will be passed across the backplane for processing by the ladder logic. Due to their length, Modbus write commands 15, 16, and 23 will have their data written to the database in the same manner as no pass-through mode. The module must complete the block transfer before it can accept another pass-through write command. The first word contains the block identification number indicating the type of command received. The second contains the length of the data in words being written across the backplane. The third word contains the destination address from the write command. The fourth contains the data. If floating-point is enabled and the data comes from a floating-point register, the fourth word will contain the first word of the data and the fifth word will contain the second word of data.

Warm Boot Block (9998)

This block does not contain any data. When the processor places a value of 9998 in word 0 of the output image, the module will perform a warm-start. This involves clearing the configuration and all program status data. Finally, the program will load in the configuration information from the Flash ROM and begin running. There is no positive response to this message other than the status data being set to zero and the block polling starting over. Cold Boot Block (9999) This block does not contain any data. When the processor places a value of 9999 in word 0 of the output image, the module will perform a hardware restart. This will cause the module to reboot and reload the program. There is no positive response to this message other than the status data being set to zero and the block polling starting over