Home > Product > Robot control system > MEAN WELL S-100-24 Relay card

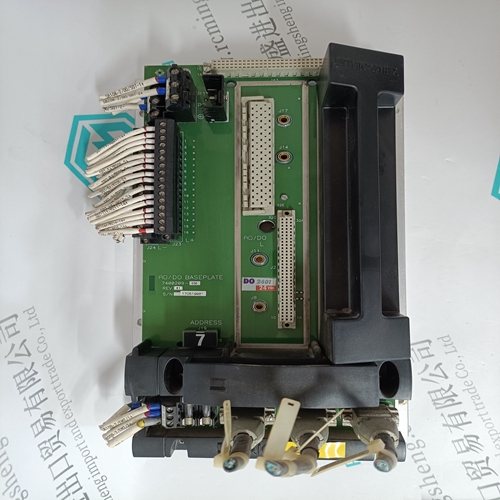

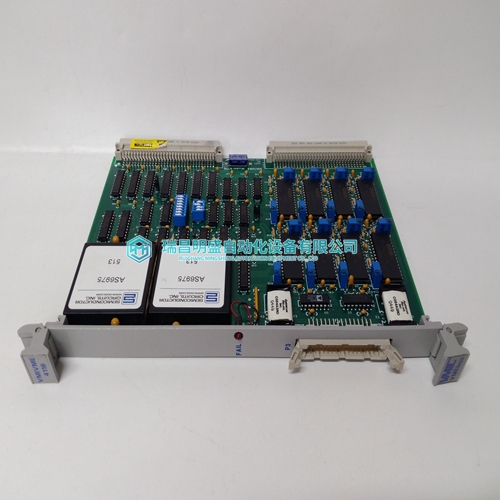

MEAN WELL S-100-24 Relay card

- Product ID: S-100-24

- Brand: MEAN WELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MEAN WELLS-100-24Relay card

- Get the latest price:Click to consult

MEAN WELL S-100-24 Relay card

The feeding frequency is MEAN WELL S-100-24, which controls the output of the frequency converter through the communication between PLC and the frequency converter, thus changing the speed of the broadband feeder and feeding the belt scale according to the required material quantity. The setting of blanking flow is to output the required value to the PLC by calculation setting, and then input it to the totalizer. After PID calculation, adjust the frequency of the broadband feeder to meet the requirements of the required blanking amount.

About us

We are professional company and we are expert in this business, we have highly experienced production team, or sales team, or purchase team, we have most advanced production line. We are reputable in the market.

Warranty: 365 days Goods status: new/used Shipping method: Courier delivery

The data of MEAN WELL S-100-24 is realized by the following program:4 is the selection input, 2200 is the starting input bit, 1 is the length, the second 4 is the selection output, and 2300 is the termination input bit. The function of this program is that the totalizer will send a pulse signal to 2300 for every 1 ton of material carried by the belt scale, and then accumulate the data to% 402996 (the output of this shift), thus forming a cycle.

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/