Home > Product > DCS control system > HONEYWELL 51196655-100 ACX633 Analog input card

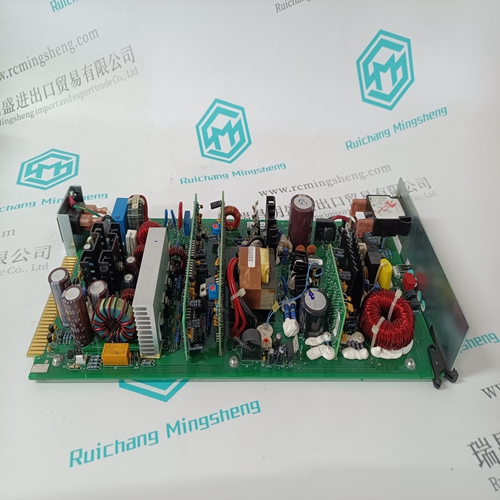

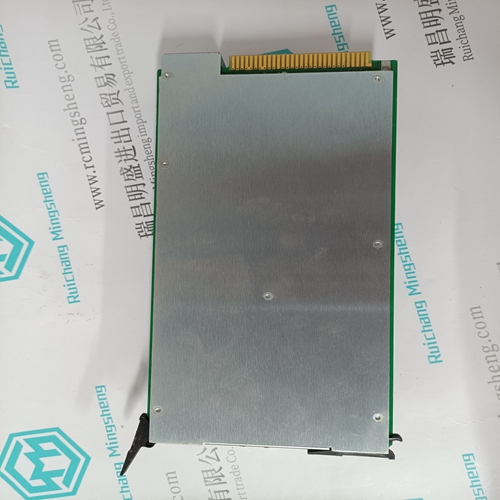

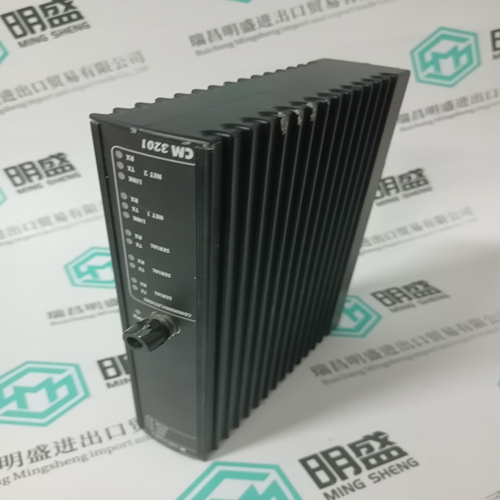

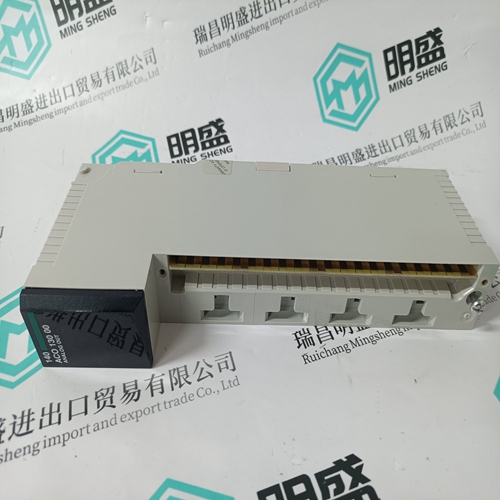

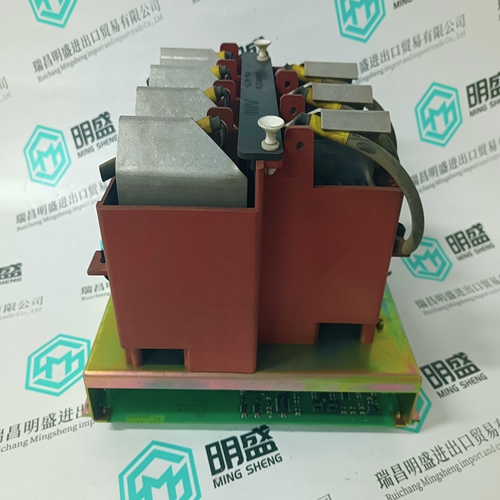

HONEYWELL 51196655-100 ACX633 Analog input card

- Product ID: 51196655-100 ACX633

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELL51196655-100 ACX633Analog input card

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

HONEYWELL 51196655-100 ACX633 Analog input card

This parameter specifies the number of program cycles between each update of the Error/Status Block data in the module. If the parameter is set to a value of 0, the data is never updated.This parameter specifies the number registers in the internal Modbus database to write over the backplane. This parameter computes the number of blocks to transfer from the module to the backplane. The number of blocks must be >= 2 for proper backplane data transfer.This parameter specifies the starting register in the internal Modbus database to fill with data read over the backplane.This parameter specifies the number registers in the internal Modbus database to consider from the read operations over the backplane. This parameter computes the number of blocks to transfer from the backplane to the module. The number of blocks must be >= 2 for proper backplane data transfer.This parameter specifies the number of consecutive backplane transfer failures before communications is disabled. If the parameter is set to a value of 0, communications is not disabled.

Description

This flag specifies if the floating-point data access functionality is to be implemented. If the float flag is set to Y, Modbus functions 3, 6 and 16 will interpret floating point values for registers as specified by the two following parameters.This parameter defines the first register of floating-point data. All requests with register values greater-than or equal to this value will be considered floating-point data requests. This parameter is only used if the Float Flag is enabled. For example, if a value of 7000 is entered, all requests for registers 7000 and above will be considered as floating-point data.This parameter defines the start register for floating-point data in the internal database. This parameter is only used if the Float Flag is enabled. For example, if the Float Offset value is set to 3000 and the float start parameter is set to 7000, data requests for register 7000 will use the internal Modbus register 3000.This parameter specifies the Modbus protocol to be used on the port. Valid Protocols are 0=Modbus RTU and 1=Modbus ASCII.

Minimum Command Delay

This parameter specifies if the CTS modem control line is to be used. If the parameter is set to N, the CTS line will not be monitored. If the parameter is set to Y, the CTS line will be monitored and must be high before the module will send data. This parameter is normally only required when halfduplex modems are used for communication (2-wire).This parameter specifies the number of milliseconds to wait between issuing each command. This delay value is not applied to retries.This parameter sets the address in the internal Modbus database where the command error data will be placed. If the value is set to -1, the data will not be transferred to the database.This parameter represents the message response timeout period in 1-ms increments. This is the time that a port configured as a master will wait before re-transmitting a command if no response is received from the addressed slave. The value is set depending upon the communication network used and the expected response time of the slowest device on the network.