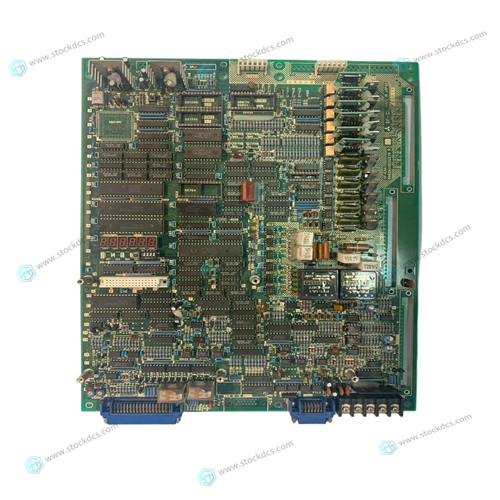

Home > Product > PLC programmable module > MITSUBISHI BN624A960H03B Tachometer Module

MITSUBISHI BN624A960H03B Tachometer Module

- Product ID: BN624A960H03B

- Brand: MITSUBISHI

- Place of origin: JAPAN

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MITSUBISHIBN624A960H03BTachometer Module

- Get the latest price:Click to consult

MITSUBISHI BN624A960H03B Tachometer Module

BN624A960H03B adopts the full closed-loop control function of the MT series operation and control integrated machine PLC of the top control technology, which can avoid the error caused by the slipping of the transmission mechanism. According to encoder feedback, accurate positioning is achieved. With version selection function, users can flexibly select the version. Moreover, by selecting the next batch of processing version, you can directly switch to reduce material waste.

About us

We are professional company and we are expert in this business, we have highly experienced production team, or sales team, or purchase team, we have most advanced production line. We are reputable in the market.

Warranty: 365 days Goods status: new/used Shipping method: Courier delivery

MITSUBISHI BN624A960H03B is a multi-pass forming roller that is configured in sequence to continuously bend metal plates and strips such as coils and strips transversely to make profiles with specific sections. The cold bending forming machine shapes and processes the steel plate through cold bending, and then automatically generates the stamping and shearing positions according to the input processing product size. According to the encoder feedback of the MT operation and control integrated machine of the top control technology, the precise positioning is achieved, so as to achieve the precise stamping and shearing. The stamping and shearing in the system are controlled by the cylinder.

This article from the temporal Ming sheng automation equipment co., LTD., reproduced please attach this link: http://www.stockdcs.com/