Home > Product > Gas turbine system > IS230SNRTH2A Combustion engine module

IS230SNRTH2A Combustion engine module

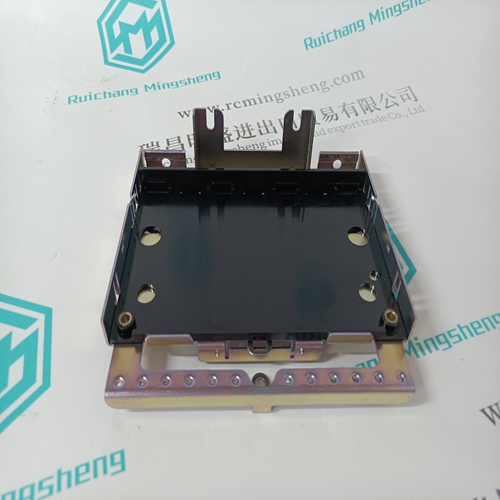

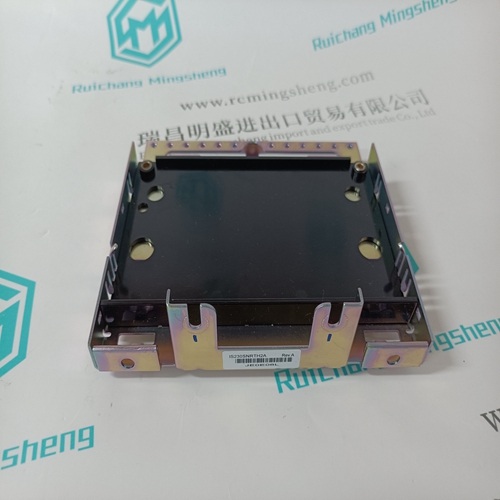

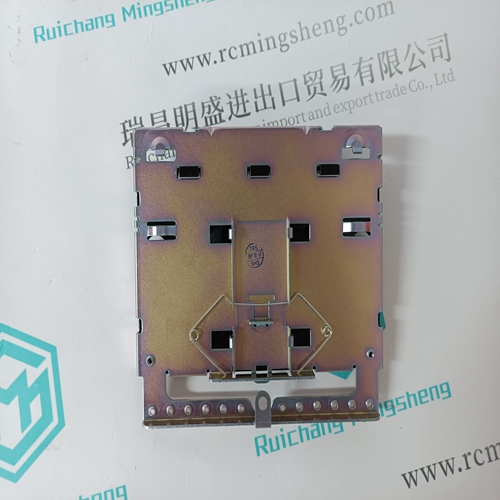

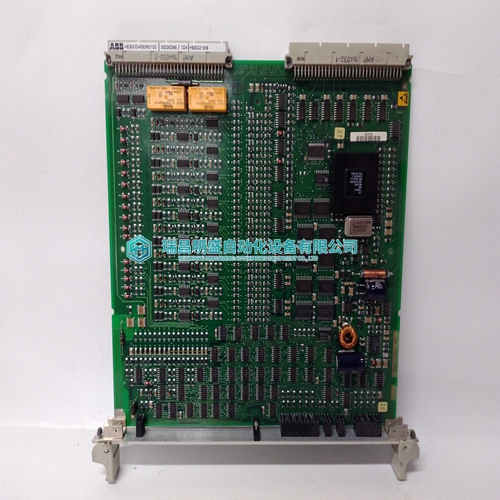

- Product ID: IS230SNRTH2A

- Brand: GE

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:IS230SNRTH2ACombustion engine module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

IS230SNRTH2A Combustion engine module

The B882–032 diagnostic output module provides 32 points that make up four groups of eight outputs. Each group of eight outputs shares an external power supply voltage. The outputs work over the range of 20.0—28.0 Vdc, true high. It is capable of driving 24 Vdc relays, solenoids, pilot lamps, and other loads rated up to 1.0 A. The B882–032 module also detects field fault conditions and turns the faulted point off for vital applications. The B882–032 diagnostic dc output module can detect open-load, over-current, over-voltage, and over-temperature conditions. The following illustration is the B882–032 simplified block diagram

The functionality of the diagnostic dc output module can be selected according to the following criteria. It can be a bi-directional module (B882) with 32 discrete outputs and 32 discrete inputs which represent fault flags for each respective output. It can also be a uni-directional module (B818) having 32 discrete outputs without fault flags.

B882 Mode

Open-load, over-current, over-voltage and over-temperature fault conditions are detected by the diagnostic output module. When an output fault is detected In the B882 mode, the module without controller intervention disarms the faulted output and reports the condition to the controller via discrete input (1x), or input register (3x) points. The point remains disarmed until the user’s logic rearms the point by turning the point back on. To turn the point back on the user’s logic must turn the point first off and then on. NOTE: If the controller attempts to turn a faulted point back on, there must be a 2 - 5 s delay from the time of a fault to the time of cycling the faulted point on. When this delay is not given, the module ignores the change. When the fault point is brought low, the fault indicator clears in the 2-5 s range. NOTE: If field power is lost, the module may detect faults. After field power is reapplied, all faults must be cleared NOTE: Clearing faults prior to restarting When a fault is detected in either the B882 or B818 mode, the source of the fault should be cleared prior to restarting the point. Failing to clear the source of a fault may result in damage to the z power source z driven field-side device z module

B818 Mode

When an output fault is detected In the B818 mode, the module without controller intervention disarms the faulted output. Faults are not reported to the controller. To turn the point back on, the user’s logic must first turn the point off and then on. NOTE: If the controller attempts to turn a faulted point back on, there must be a 2 - 5 s delay from the time of a fault to the time of cycling the faulted point on. When this delay is not given, the module ignores the change. When the faulted point is brought low, the fault indicator clears in the 2 -5 s range. NOTE: Loss of power. If field power is lost in the B818 mode, the module may detect faults that are not visible to the controller. z After field power is reapplied, the points must be turned off and then on for all on states.