Home > Product > PLC programmable module > PROSOFT 6105-WA-PDPS Communication module

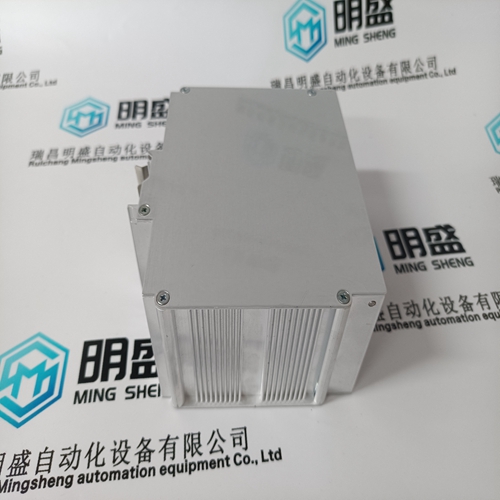

PROSOFT 6105-WA-PDPS Communication module

- Product ID: 6105-WA-PDPS

- Brand: PROSOFT

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PROSOFT6105-WA-PDPSCommunication module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

PROSOFT 6105-WA-PDPS Communication module

An external contact may be used as a turbine start-up permissive. When programmed for this functionality, the contact input must be closed in order for a ‘RUN’ command to be executed. Should the contact be open when a ‘RUN’ command is given, an alarm will be issued and the 505 display will indicate that the start permissive was not met (Start Perm Not Met). The alarm does not need to be cleared but the contact must be closed before the 505 will accept the ‘RUN’ command. After ‘RUN’ has been accepted, the start permissive contact will have no effect on operation. Example: This input could be connected to a Trip & Throttle valve’s closed limit switch to verify that it is in the closed position before a turbine start-up is performed.

The 505 has five PID controllers that can affect the demand to the main inlet steam valve; the speed/load PID controller, an Acceleration PID, two Auxiliary PID controllers, and the Cascade PID controller. Depending on the configuration of the 505, these PIDs interact differently with each other. Please refer to the Block diagrams listed earlier in this manual to fully understand PID relationships.

Open Wire Detection on MPU Speed Signals

The 505 automatically verifies continuity of the speed MPU circuits each time it prepares to issue a “Ready to Start” status message. If an open wire is detected it will issue an alarm for this input, if all MPU’s appear to have open wires a Trip is initiated. This open wire test can be done manually any time the turbine is stopped and the speed is zero. It is also possible to Disable the automatic test at start from this screen The screen is located under Analog Inputs/Speed Signal X/Open Wire Test.

Zero Speed Signal Override The 505 issues a shutdown if no speed signal is detected (magnetic pickup voltage less than 1 Vrms or speed is less than the ‘Failed Speed Level’). To allow the control to start with speed not being sensed, this shutdown logic must be overridden. The control can be configured to provide a manual or an automatic speed override. For added protection, a timed limit on the override is available. The status of the MPU override logic may be viewed in the Service mode or through Modbus communications. The override logic applies to both passive and active speed probes.

Manual Speed Override

If the ‘Override MPU Fault’ function is assigned to a contact input, the loss-of- speed detection logic is overridden as long as this contact is closed; until the maximum time expires. Opening the assigned contact input, disables the override logic, and re-arms the loss-of-speed detection circuit. Once re-armed, a system shutdown is executed if the sensed speed drops below the ‘Failed Speed Level’ setting. A maximum override time limit is provided as an extra level of protection, in the event the contact input is left closed. A ten minute maximum time limit is applied to a Manual override command (as defaulted in the Service Mode). This time starts when the RUN command is initiated and re-arms the loss-of-speed detection when the time expires. The 505 will execute a system shutdown if turbine speed isn’t above the ‘Failed Speed Level’ setting when the time expires.