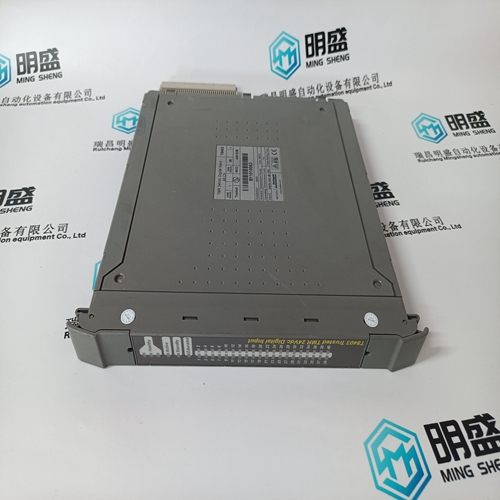

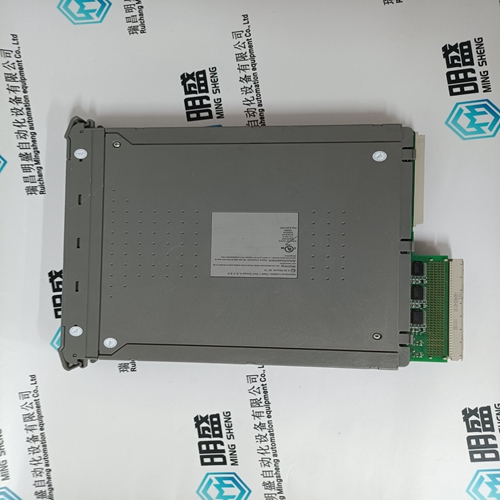

Home > Product > PLC programmable module > ICS TRIPLEX T8403 industrial module

ICS TRIPLEX T8403 industrial module

- Product ID: T8403

- Brand: ICS TRIPLEX

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ICS TRIPLEXT8403industrial module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

ICS TRIPLEX T8403 industrial module

If the Manual Speed Override option is not programmed, the Automatic Speed Override logic is used by the 505 to override the loss-of-speed signal shutdown logic during a turbine start-up. With the Automatic Override logic, the loss-ofspeed signal failure is armed when the turbine trips and remains armed until the sensed turbine speed exceeds the programmed (‘Failed Speed Level’ setting + 50 rpm). Once turbine speed exceeds this level, the loss of speed detection circuit is re-armed and the control will execute a system shutdown if sensed speed drops below the ‘Failed Speed Level’ setting. For added protection, a timed limit is available on the automatic speed override function. The timed speed override timer deactivates the loss-of-speed override logic after the programmed time expires. If programmed, this timer starts counting down once a ‘START’ command has been issued. This timer when programmed provides an extra level of protection, in the event both speed input probes are failed when the unit is started. This timer may be programmed in the 505’s Service mode

Acceleration Limiter

The acceleration limiter is available for startup to significantly reduce speed overshoot to the minimum controllable speed setpoint at turbine start. The Acceleration Limiter is disabled after reaching the minimum controllable speed and the 505 will continue the start sequence via the Speed PID. If the Acceleration Limiter is set to be used via the Service menu, then it will control speed at the ‘Rate to Min’ rate (RPM/s), as set in the Turbine Start configuration, until the Speed PID is in control at the Minimum Controllable Speed. When the Start Sequence is set to “No Start Sequence”, the Minimum Controllable Speed is Minimum Governor. When the Start Sequence is set to “Idle/Rated Sequence” or “Auto Start Sequence”, the Minimum Controllable Speed is the Lowest Idle setting.

Using the Acceleration Limiter feature carries some risk without proper tuning of the Acceleration PID. Please monitor actuator behavior at turbine start. Verify there is no instability in the Acceleration Controller that may result in system damage during oscillation of the actuator/valve if it is unstable. When the response of the Acceleration Controller is over-damped, it may follow the speed setpoint very slowly at startup or even move the valve closed but, after this, acceleration should be controlled fairly well until the Acceleration Limiter logic is disabled.

Turbine Start Mode Procedures

Manual Start Mode The following start-up procedure is employed when the Manual start mode is configured: 1. Issue a RESET command (to reset all alarms and shutdowns) 2. Issue a START command (verify T&T valve is closed before issuing) At this point the 505 will ramp open the governor valve to its maximum position at the ‘Valve Limiter Rate’. The speed set point will ramp from zero to the minimum controlling speed setting at the ‘Rate To Min’ rate. 3. Open Trip & Throttle valve at a controlled rate When turbine speed increases to the minimum controlling speed, the 505’s Speed PID will take control of turbine speed by controlling turbine inlet valve position. 4. Open Trip & Throttle valve to 100% Speed remains controlled at the minimum controlling point until action is taken by the operator or the ‘Auto Start Sequence’, if programmed, begins controlling. The ‘Limiter Max Limit’, ‘Valve Limiter Rate’ and ‘Rate To Min’ settings are tunable in the Service mode.

The trip-and-throttle valve must be closed before pushing the ‘RUN’ key in Manual Start mode. If a START command is given while the trip-and-throttle valve is open, there exists a possibility of turbine runaway with resultant serious injury or loss of life.