Home > Product > Robot control system > 033.733.002.S Dc channel CARDS

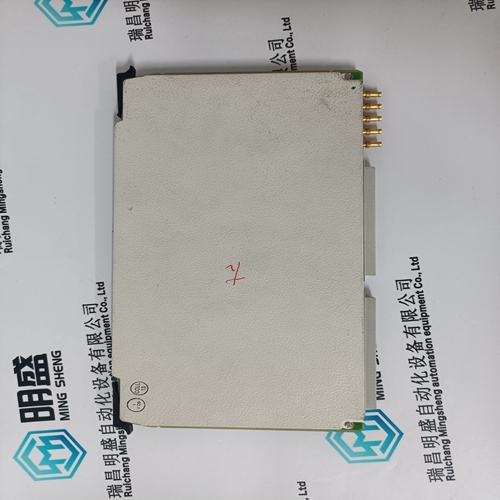

033.733.002.S Dc channel CARDS

- Product ID: 033.733.002.S

- Brand: other

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:033.733.002.SDc channel CARDS

- Get the latest price:Click to consult

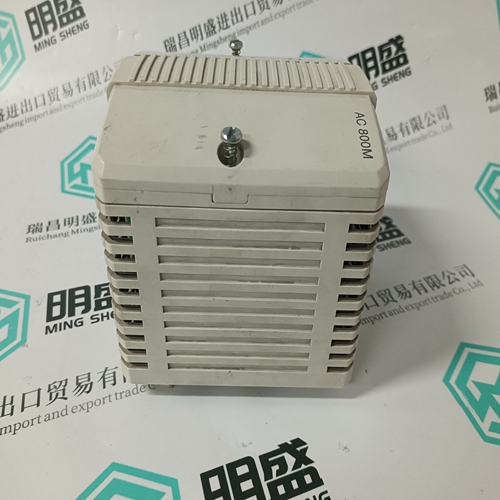

The main products

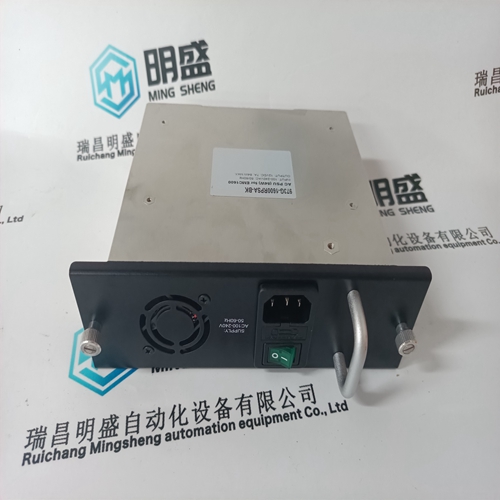

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

033.733.002.S Dc channel CARDS

A Ramp-to-Idle speed or Ramp-to-Rated speed command may be selected from the 505 keypad, contact input, or Modbus communications. The last command given from any of these three sources dictates the function performed.

If a 505 contact input is programmed to select between Idle or Rated speeds, Idle speed is selected when the contact is open and rated speed is selected when it is closed. The Idle/Rated contact can be either open or closed when a trip condition is cleared. If the contact is open, it must be closed to initiate a Ramp-toRated speed. If the contact is closed, it must be opened and re-closed to initiate a Ramp- to-Rated speed. When the turbine is used for mechanical drive applications, rated speed may be set at the minimum governor speed setting. When the turbine is used to drive a generator, the ‘rated speed’ setting may be set at or between the minimum governor and synchronous speed settings. All pertinent Idle/Rated parameters are available through the Modbus links, refer to Chapter 6 for a complete listing

The Idle/Rated function

can be used with any 505 start mode (manual, semiautomatic, automatic). When a START command is issued, the speed set point will ramp from zero rpm up to and hold at the ‘Idle Setpt’ setting. When a ramp- to-rated command is given, the speed set point ramps to the ‘Rated Setpt’ setting at the ‘Idle/Rated Rate’. While ramping to a Rated speed, the set point can be stopped by a raise or lower speed command or a valid entered speed set point. The 505 will inhibit a ramp-to-idle speed or ramp-to-rated speed command, if the Generator Breaker is closed, Remote Speed Set Point is enabled, Cascade PID is in control, or the Auxiliary PID is in control (as defaulted in the Service Mode). Alternatively, the 505’s ‘Idle Priority’ and ‘Use Ramp to Idle Function’ Service mode settings can be configured to change the defaulted idle/rated logic.

The 505 can be configured to utilize an Automatic Start Sequence to start the turbine. This sequencing logic allows the 505 to perform a complete controlled system start-up from zero speed to rated speed. With this function, the turbine’s starting ramp rates and idle speed hold times depending on either the length of time the unit was shutdown or upon optional temperature input signals. This sequence logic may be used with any of the three start modes (manual, semiautomatic, automatic), and is initiated by a ‘RUN’ command.

Automatic Start Sequence

With this function, when a ‘START’ command is given, the Automatic Start Sequence ramps the speed set point to a low idle set point, holds at this setting for the set duration, ramps the speed set point to the Idle-2 setting, holds at this setting for a the set duration, ramps the speed set point to Idle-3 setting, holds at this setting for the set duration, then finally ramps the speed set point to the programmed rated turbine speed setting. All ramp rates and hold times are programmable for both hot start and cold start conditions. The control differentiates between hot and cold starts by using a “Hours-Since-Trip” timer or a contact input. When using the “Hours-Since-Trip” timer, the timer starts when a shutdown has been executed and turbine speed has decreased below the low idle speed setting