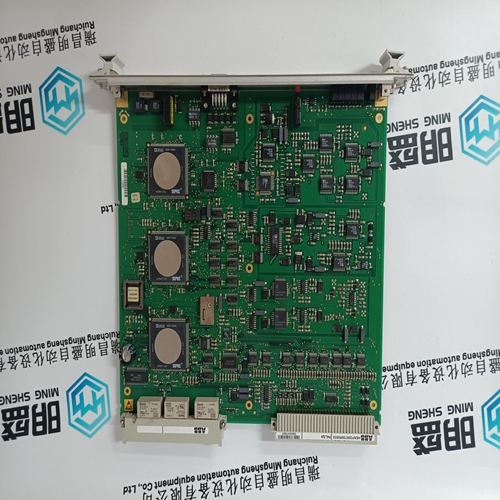

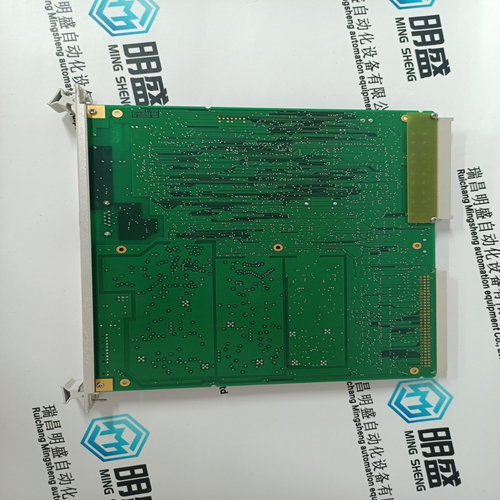

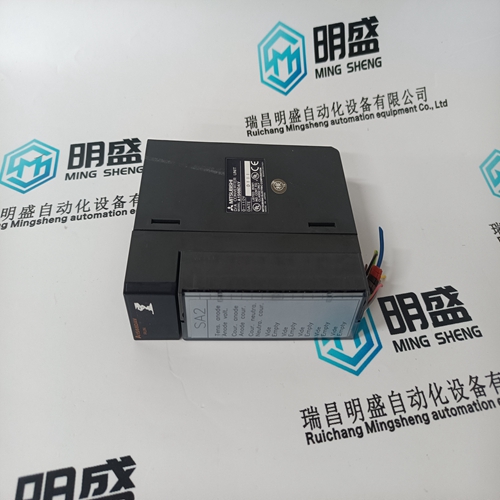

Home > Product > DCS control system > P4LQA HENF209736R0003 Control module

P4LQA HENF209736R0003 Control module

- Product ID: P4LQA HENF209736R0003

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:P4LQA HENF209736R0003Control module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

P4LQA HENF209736R0003 Control module

Depending on a unit’s size, health, and running status, an operator may select which unit is designated as the plant Frequency control unit if or when the plantto-utility tie breaker opens. Frequency control can be Armed at any time, but it will only go into control when the generator breaker is closed and the utility tie breaker is open. Only one unit at a time should have its Frequency control mode armed. If multiple units try to control plant frequency at the same time, they may fight and cause system instability, with the potential of damage to the equipment due to overloading or reverse-powering a machine. If the ‘Use Freq Arm/Disarm’ setting box is unchecked, Frequency control is always Armed and the unit will go into Frequency control when the utility tie contact is open. If the program’s ‘Use Freq Arm/Disarm’ setting box is checked, then Frequency control must first be armed before the unit will switch into Frequency control when the utility tie contact is open.

Frequency Arm/Disarm

The Frequency Arm/Disarm feature can be used only when load sharing is not being performed, to allow multiple units to operate on the same isolated bus. With this feature, one unit on a multiple unit isolated bus controls frequency and the other units operate in a unit-load mode. The unit controlling frequency is referred to as the “Swing Machine” because its load will swing (vary) depending on the load of the plant. Caution should be taken with this configuration to not overload or reverse power the “Swing Machine”. This feature, when programmed, allows an operator to Arm or Disarm a unit’s Frequency control mode while it is in operation. When Armed, a unit will switch to Frequency control if the plant-to-utility tie breaker opens. When Disarmed, a unit will stay in a unit-load control mode when the plant-to-utility tie breaker opens. To use this feature, the program’s ‘Use Freq Arm/Disarm’ setting box must be checked, the Sync/Load Sharing mode cannot be programmed, and a discrete command must programmed. The Frequency Arm/Disarm mode can be selected from a programmed contact input, Function key, or Modbus command. When the programmed contact input is closed the unit’s Frequency control mode is Armed. When the programmed contact input is open the unit’s Frequency control mode is Disarmed.

Speed Control Dynamics

The 505 has a variety of options for the setting of dynamics (PID gain settings). When a system needs variable response times, due to changing system conditions, these dynamic variables allow the Speed PID to be tuned for optimal response. There values are separated into 2 main operational conditions, OffLine and On-Line. Off-Line and On-Line - When the 505 is configured for a generator application, the utility tie and generator breakers determine which set of dynamics is used by the Speed PID. The speed PID’s off-line dynamics are selected when either the utility tie or generator breakers are open. The Speed PID’s on-line dynamics are selected if both breakers are closed (see Table 3-2). When not configured for a generator application, the 505 uses the programmed ‘Min Governor Speed Set Point’ setting to determine which set of dynamic values are used by the Speed PID. The Speed PID’s off-line dynamics are selected when turbine speed is below the ‘Min Governor Speed Set Point’ setting. The Speed PID’s on-line dynamics are selected when turbine speed is above the ‘Min Governor Speed Set Point’ setting. (see Table 3-2).