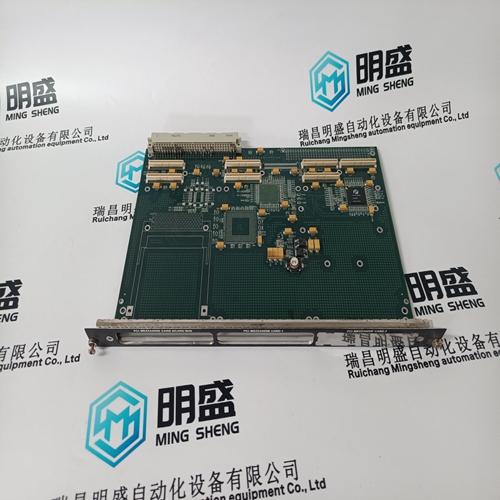

Home > Product > Robot control system > RAMIX PMC237C-008EMI connector card

RAMIX PMC237C-008EMI connector card

- Product ID: PMC237C-008EMI

- Brand: RAMIX

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:RAMIXPMC237C-008EMIconnector card

- Get the latest price:Click to consult

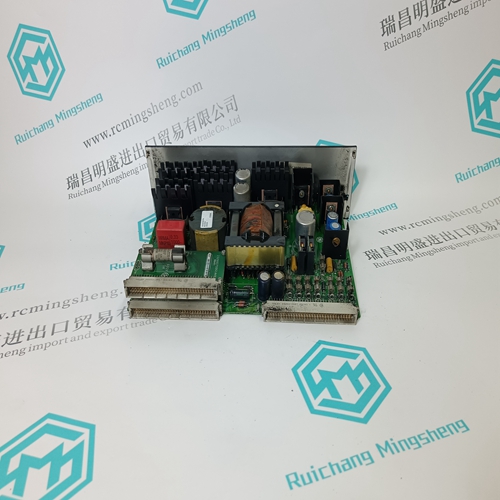

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

RAMIX PMC237C-008EMI connector card

These products can be used as a synchronizer only or as a synchronizer and load control. When used as a synchronizer only, the 505 must be configured to accept the products analog Speed Bias signal and have this input enabled. A ‘Sync Enable’ contact input can be programmed to enable the 505’s synchronizing input when synchronization is desired. The Sync Enable command becomes disabled when the generator breaker closes, however, it may reenabled again to allow the load management product to perform tie breaker synchronizations. To re-enable this input the ‘Sync Enable’ contact must be opened and re-closed. Typically a double pole single throw (DPST) switch is used on a site’s synchronizer control panel to select automatic synchronizing by enabling both the load management product sync mode and 505 analog input at the same time. Alternatively this signal can be sent to the 505, and the 505 can configure a relay output to send this Enable command to the synchronizer. To configure the 505 to utilize a load management product for generator synchronization only, program the ‘Synchronizing input’ function setting and program the ‘Sync Enable” function to a ‘CONTACT INPUT X’ setting. The ‘Synchronizing input’ function has a menu to allow this signal to come from the digital communication link, or from an Analog Input. If an AI is used, the range and gain settings are preset and are tunable only in the Service mode. Thus the 4 mA and 20 mA Program Mode settings for the Synchronizing input are irrelevant and are not used by the function’s operation. See Volume #2 of this manual.

Remote Speed Set Point Status Messages

The Remote Speed Set Point may be in one of the following states (505 front panel screen messages): Disabled—The remote set point function is not enabled and will have no effect on the speed set point. Enabled—The remote set point has been enabled. Active—The remote set point is in control of the Speed set point but the speed PID is not in control of the actuator output. In Control—The remote set point is in control of the Speed set point and the speed PID is in control of the actuator output. Inhibited—RSS cannot be enabled. The input signal has failed, a controlled stop is selected, the unit is shut down, or RSS is not programmed. When enabled, the Remote Speed set point may not match the Speed set point. In this case, the Speed set point will ramp to the Remote Speed set point at the programmed ‘Speed Set Point Slow Rate’ setting (as defaulted in the Service mode). Once in control, the maximum rate that the Speed set point will ramp, for a RSS change, is at the programmed ‘Remote Speed Set Point Max Rate’ setting. If the ‘Remote Speed Set Point Max Rate’ were set at 10 rpm/s and the Remote Speed set point analog input instantly moved from 3600 rpm to 3700 rpm, the Speed set point will move to 3700 rpm at 10 rpm/s.

Synchronization

Automatic generator synchronization can be performed through a Woodward EGCP-3, easYgen, or DSLC-2. The DSLC-2 product is the easiest to integrate with the 505 as it can be integrated via a digital communication connection by using the Woodward Links wizard. In some cases, the analog input signal interfaces described below are not required, but can be used as a redundant signal if desired. These products connect to a 505 analog input to bias the 505’s speed set point directly to vary generator speed, frequency and phase. Optionally these products can interface with the unit voltage regulator to match system voltage across a generator breaker. When the 505 is configured for a Generator application, a special speed set point rate (Sync Window Rate) is used to increase set point resolution around synchronous speed. This allows for tighter set point control to accommodate synchronizing manually or by an automatic synchronizer which interfaces to the 505 discretely. This Sync rate is defaulted to two rpm/s and is only adjustable through the 505’s Service mode. This rate is only used when the generator breaker is open and the actual speed is within +10 rpm of rated speed (also tunable through the Service mode).