Home > Product > Gas turbine system > 8910-PS-DC Gas turbine electrical module

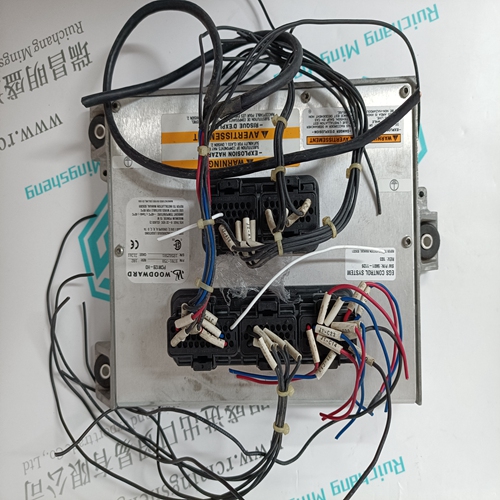

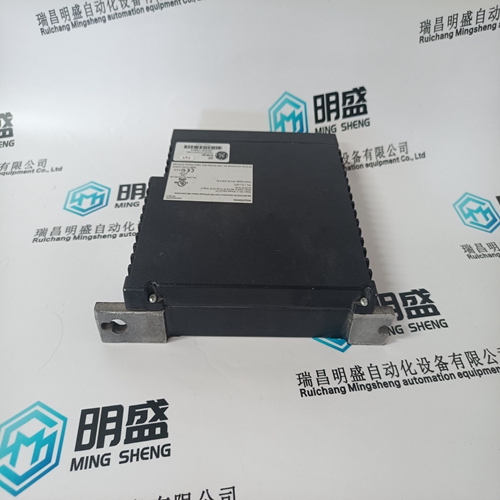

8910-PS-DC Gas turbine electrical module

- Product ID: 8910-PS-DC

- Brand: GE

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:8910-PS-DCGas turbine electrical module

- Get the latest price:Click to consult

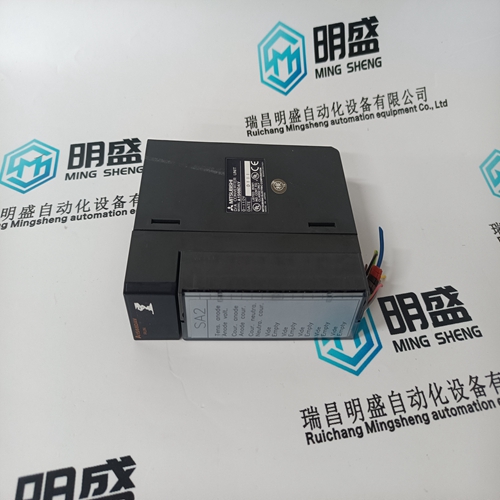

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

8910-PS-DC Gas turbine electrical module

The Overview screen will adapt to the configuration of the 505 and show all configured options. During normal run operation, this screen should provide the user with all of the primary turbine parameter values and operational status. The menu bar functions will allow the user to use typical operational commands related to the control loop selected – such as directly entering a setpoint or enabling or disabling a controller while remaining on the Overview page

The Speed Control screen will adapt to the configuration of the 505 and show all configured options. During normal run operation, this screen provides the user with all details that are related to the turbine when operating in speed control. The menu bar functions will allow the user to access a number of other screens that are related to speed control, such as directly entering a setpoint, access to the valve limiter feature, adjusting speed control dynamic settings, enabling or disabling a remote speed setpoint or performing an Overspeed test. For generator units the breaker status of the breakers is shown and the menu bar will give the user access to Enabling the synchronizer.

Valve Demand Screen

The Valve Demand screen will adapt to the configuration of the 505 and show all configured options that can affect the final output demand to the valve. During normal run operation, this screen provides the user with a clear picture of what control or ramp is controlling the valve demand output. The Low Signal Select (LSS) bus will output the lowest value seen at its inputs. The valve logic box represents options that may be use to adjust this value (such as valve linearization and/or pressure compensation) prior to output to the HP valve. If these options are not used, the HP valve demand output will always equal the LSS value. During normal operation the Valve Limiter setting is at 100% and not limiting. Typically, the only time this parameter is adjusted is during a start sequence or to troubleshoot system dynamics problems. The menu bar will allow the user to access the valve limiter setpoint and the manual valve demand (if configured for use).

The Cascade Control screen

will adapt to the configuration of the 505. During normal run operation, this screen provides the user with all details that are related to the cascade control loop. The cascade control output determines the setpoint for the speed control. This allows the 505 to vary the speed control setpoint as it relates to another process variable selected by the user. The menu bar functions will allow the user to access a number of other screens that are related to cascade control, such as directly entering a setpoint, access to the valve limiter, or adjusting cascade control dynamic settings.

The Controllers screen will adapt to the configuration of the 505 and show all configured options. During normal run operation, this screen provides the user with information similar to the Overview, but in a graphical gauge view. It provides larger values for distance viewing and control PID information which is useful for monitoring when the 505 is near transition points between controllers or limiters. The menu bar functions will allow the user to use typical operational commands related to the control loop selected – such as directly entering a setpoint or enabling or disabling a controller while remaining on the Controllers page