Home > Product > DCS control system > GFD563A101 3BHE046836R0101 Control module

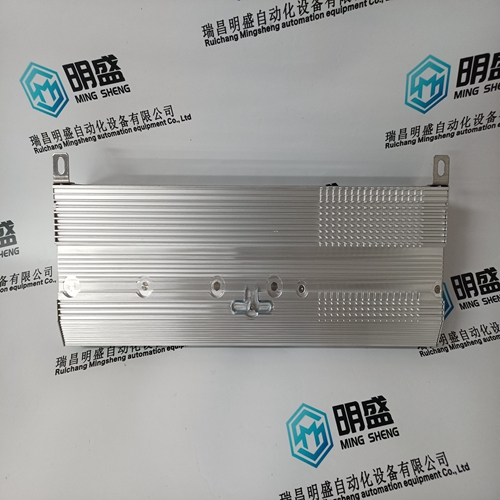

GFD563A101 3BHE046836R0101 Control module

- Product ID: GFD563A101 3BHE046836R0101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GFD563A101 3BHE046836R0101Control module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

GFD563A101 3BHE046836R0101 Control module

Use a motor under an appropriate environmental condition. Using a motor in an adverse environment may cause a failure or trouble in it. Refer to their respective specification manuals for details of the operating and environmental conditions for motors. - Do not apply a commercial power source voltage directly to a motor. Applying a commercial power source voltage directly to a motor may result in its windings being burned. Be sure to use a specified amplifier for supplying voltage to the motor. - For a motor with a terminal box, make a conduit hole for the terminal box in a specified position. When making a conduit hole, be careful not to break or damage unspecified portions. Refer to an applicable specification manual. - Before using a motor, measure its winding and insulation resistances, and make sure they are normal. Especially for a motor that has been stored for a prolonged period of time, conduct these checks. A motor may deteriorate depending on the condition under which it is stored or the time during which it is stored. For the winding resistances of motors, refer to their respective specification manuals, or ask FANUC. For insulation resistances, see the following table.

CAUTIONS RELATING TO MOUNTING

- Check the specification code of the amplifier. Check that the delivered amplifier is as originally ordered. - Mount a ground fault interrupter. To guard against fire and electric shock, fit the factory power supply or machine with a ground fault interrupter (designed for use with an inverter). - Securely ground the amplifier. Securely connect the ground terminal and metal frame of the amplifier and motor to a common ground plate of the power magnetics cabinet. - Be aware of the weight of the amplifier and other components. Control motor amplifiers and AC reactors are heavy. When transporting them or mounting them in the cabinet, therefore, be careful not to injured yourself or damage the equipment. Be particularly carefull not to jam your fingers between the cabinet and amplifier. - Never ground or short-circuit either the power supply lines or power lines. Protect the lines from any stress such as bending. Handle the ends appropriately. - Ensure that the power supply lines, power lines, and signal lines are securely connected. A loose screw, loose connection, or the like will cause a motor malfunction or overheating, or a ground fault.

To use a motor as long as possible, perform periodic maintenance and inspection for it, and check its winding and insulation resistances. Note that extremely severe inspections (such as dielectric strength tests) of a motor may damage its windings. For the winding resistances of motors, refer to their respective specification manuals, or ask FANUC. For insulation resistances, see the following table.

Insulate all exposed parts that are charged.

- Never touch the regenerative discharge resistor or radiator directly. The surface of the radiator and regenerative discharge unit become extremely hot. Never touch them directly. An appropriate structure should also be considered. - Close the amplifier cover after completing the wiring. Leaving the cover open presents a danger of electric shock. - Do not disassemble the amplifier.

- Ensure that the cables used for the power supply lines and power lines are of the appropriate diameter and temperature ratings. - Do not apply an excessively large force to plastic parts. If a plastic section breaks, it may cause internal damage, thus interfering with normal operation. The edge of a broken section is likely to be sharp and, therefore, presents a risk of injury.

- Do not step or sit on the amplifier. Also, do not stack unpacked amplifiers on top of each other. - Use the amplifier in an appropriate environment. See the allowable ambient temperatures and other requirements, given in the corresponding descriptions. - Protect the amplifier from corrosive or conductive mist or drops of water. Use a filter if necessary. - Protect the amplifier from impact. Do not place anything on the amplifier.